Vehicle Speed Sensors

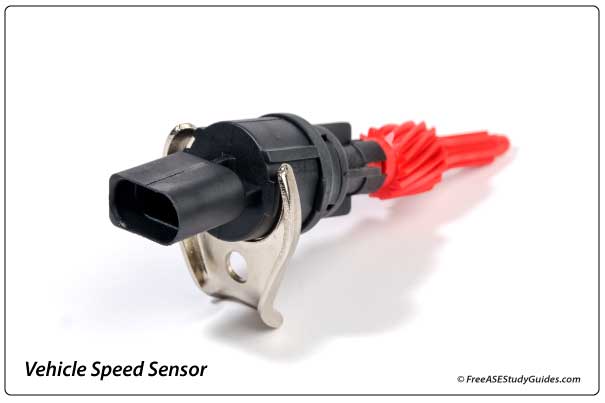

(VSS) Vehicle Speed Sensors input vehicle speed data to the transmission control module for shift control. The signal is also used by other systems on the CAN, like cruise control and ABS (anti-lock brakes), only to name a few. Most mount directly on the transmission or transaxle case. They send a varying frequency to a meter in the TCM, indicating vehicle speed.

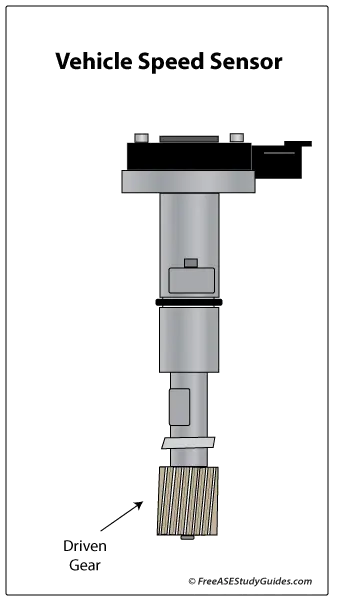

A gear on the transmission's output shaft drives the sensor. The gear can be machined and held in place by a bolt or fastened by a clip. The driven gear is in mesh with the drive gear located on the output shaft at all times. The sensor's case bore and the output shaft gear could be an underlying cause of premature driven gear wear. The driven gear is typically made of plastic, intentionally making it softer than the drive gear.

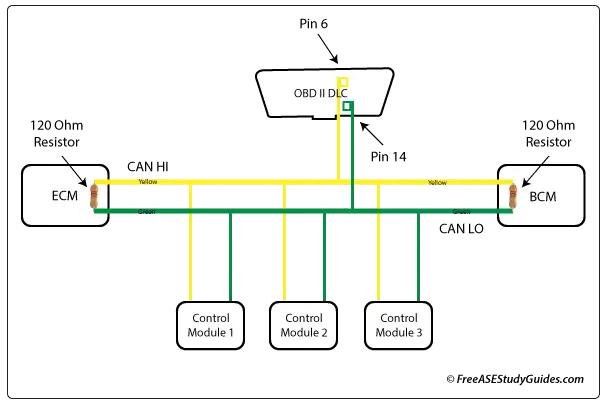

As the shaft of this sensor spins, it generates an on-off signal to the vehicle's PCM and TCM. The PCM converts this signal into vehicle speed. Control modules communicate over the CAN bus with twisted pair wiring.

The CAN or controller area network is a serial priority-based messaging protocol invented by Bosch. It has proven reliable and the industry standard for high-speed automotive network communications.

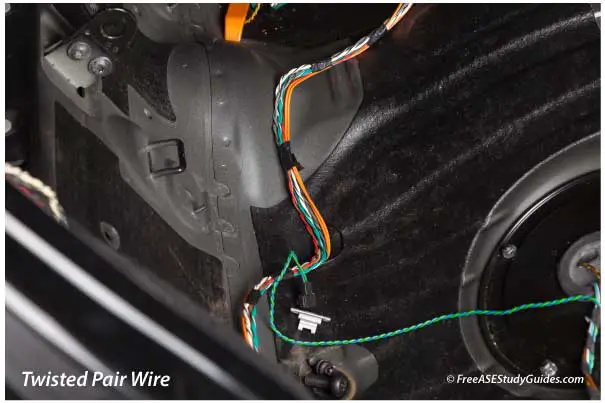

The twisted pair wire used on the CAN bus allows electromagnetic interference to cancel itself out. In addition, differential signaling reduces the effects of noise on the network.

If a fault code (P0500 range) is retrieved, visually inspect the wiring and connectors for wear or damage. The sensor can be tested with a scanner and multimeter and compared to specifications.