Torsion Bar Adjustment

Both cars and trucks have torsion bar suspensions. They provide the ride comfort and suspension of coil springs and leaf springs with the added benefit of ride height adjustability. They can be longitudinal or transverse. Weak torsion bars or worn anchors and bushings alter the vehicle's ride height, affecting stability and tire wear.

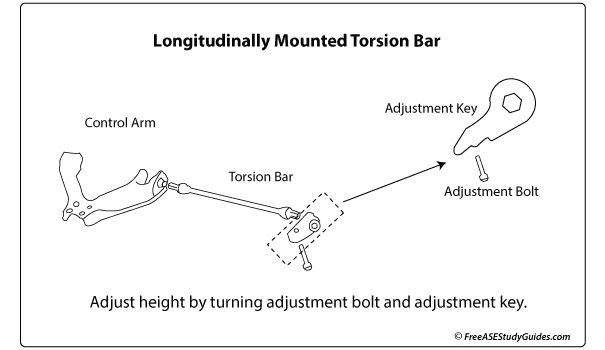

A typical longitudinally designed torsion bar is a long steel bar fitted between the frame of the vehicle and one of the control arms. It may be the upper or lower control arm, usually the lower. Turn the adjuster or key at the frame end of the torsion bar to adjust the height. These, sometimes called hex keys, apply the twisting motion needed for vehicle suspension and adjustment. The left and right sides are often different and not interchangeable.

Several factors are involved in adjusting a vehicle's ride height with torsion bar suspension. The control arm's angle and the torque or twisting motion applied to the torsion bar are essential. On some vehicles, the CV joints will wear prematurely if the ride height is over-adjusted.

The dimensions and thickness of the bar itself are essential. Vehicle manufacturers and aftermarket companies provide heavy-duty bars by increasing the thickness from 22mm to 24mm. A manufacturer may install a thicker bar for a bigger, heavier engine. Depending upon the application, different materials are used to construct the bars.

Take height measurements before and after adjustments. A good spot would be between the lower part of the fender and the top of the wheel rim. Measure the distance from the base of the bolt head to its mating surface as a reference point. Tightening this bolt turns a key that twists the torsion bar. This extra torque applies more force to the control arm, raising the vehicle to the desired height. Check for TSBs or any special procedures before adjusting the height of a vehicle with torsion bars.