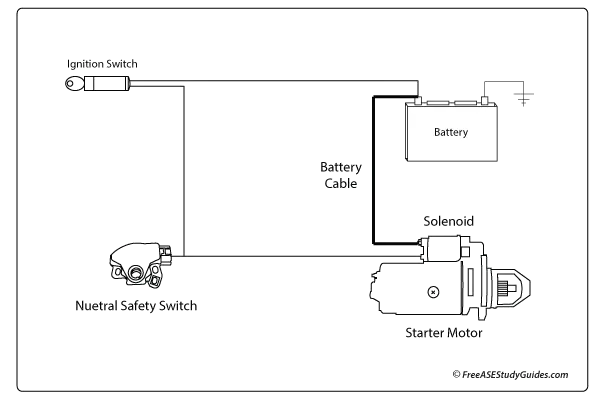

Starting System Components

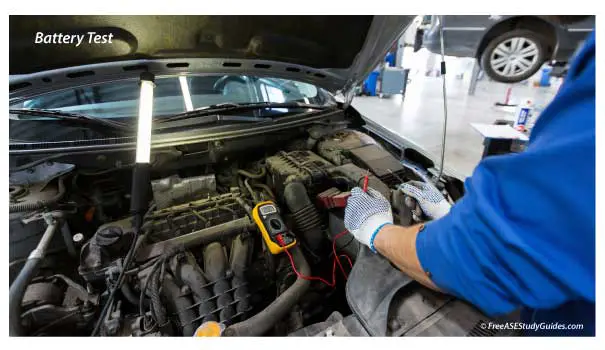

The battery is the first place to look when a vehicle has a slow start or no start condition. Check the battery posts and make sure the terminals are fastened tightly to the posts.

Battery: Perform a voltage test using a voltage meter. A good battery will have 12.6 volts. There are six cells in series at 2.1 volts each. A hydrometer measures the battery electrolyte's specific gravity. A fully charged battery will have a specific gravity of 1.265 at 80° F.

Battery Load Test

Perform a battery load test to see if service or replacement is necessary. First, determine the load by retrieving the CCA from the battery case and reducing this number by half. The test discharge rate is one-half of the battery's cold-cranking rating. Apply this load to the battery for 15 seconds. Battery voltage must remain above 9.6 volts at 70° F.

Battery Cables

Battery Cables: Perform voltage drop tests on the starter and ground cables. A loose or corroded ground connection between the engine block and battery negative cable will cause a sluggish or no-start condition.

Battery cables come in different gauges. Years ago, battery cables were six gauge because there were not as many accessories requiring higher amperage. Today's vehicles often come with factory two and four-gauge battery cables, capable of handling higher current rates. A two-gauge cable is thicker and can handle more current than a six-gauge cable.

Starter Motor

Solenoid and Starter Motor: A starter solenoid is an electromagnetic device that serves two purposes. It completes the circuit between the battery and the starter motor and moves the gear into mesh with the engine's ring gear.

The starter motor will wear, causing a high current draw. Typically the starter motor is removed and replaced. Rebuilders replace components like brushes, windings, and bushings before returning the starter to service.