Contaminated Engine Oil

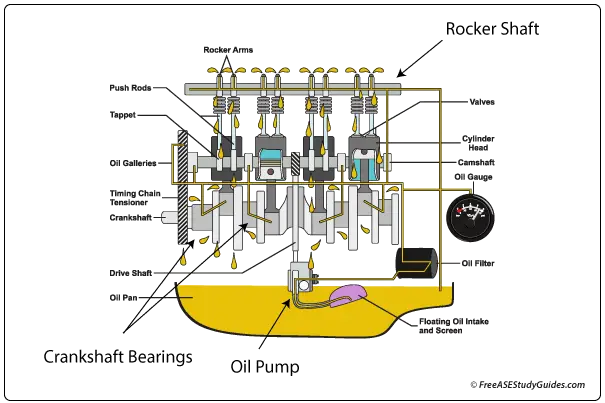

Engine oil reduces bearing friction, transfers heat, and protects from corrosion. Its primary function is to lubricate and cool engine components providing a cushion for bearings and transferring heat from the engine's cylinders.

A good oil filter traps debris from 20 microns up. Oil contamination occurs when solid matter, dust, and dirt enter the engine through the air filter, breather, or vent tube and mixes with the oil. These particles flow with the oil, scoring the cylinder walls and piston skirts, scratching parts, and creating engine component wear particles.

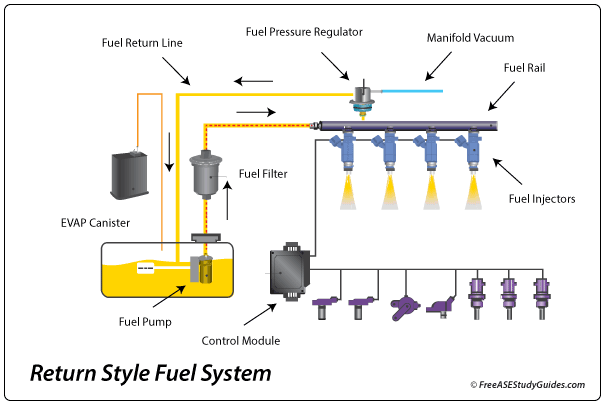

Fuel

Fuel enters the crankcase past the piston rings (blowby), lowering the oil's viscosity, reducing corrosion protection, and increasing its flashpoint and system wear. Excessive idle time, cold-running engines, and mechanical issues like leaking fuel injectors exacerbate the problem. In addition, direct fuel injection engines operate at high fuel pressures and are especially susceptible to fuel dilution, sludge, and varnish.

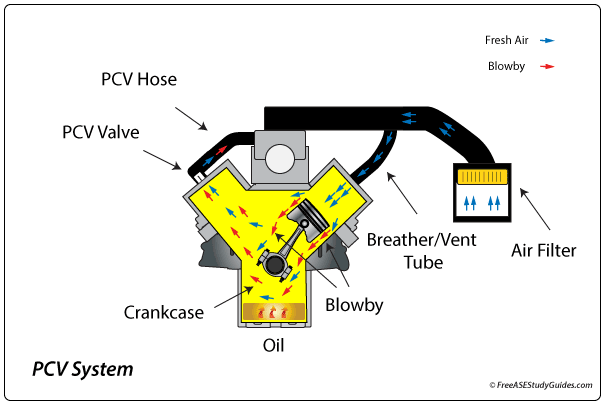

Water

Water reduces lubricity leading to component wear, and coolant reduces oil viscosity and creates a thick sludge. The PCV system vents crankcase vapors to the intake manifold for combustion. In addition, it reduces the chance of water intrusion.

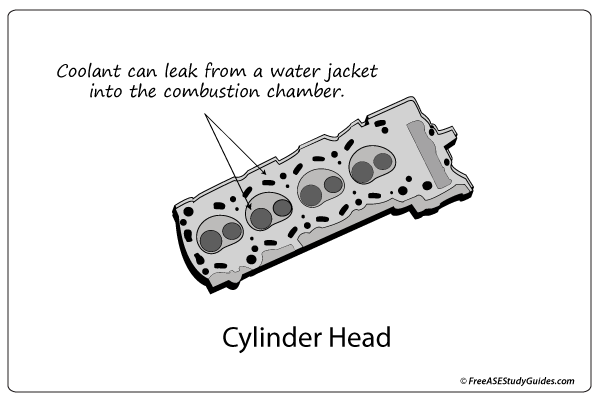

Coolant

Coolant enters the crankcase through a blown head gasket or leaking intake manifold jacket and mixes with the oil. As a result, the oil turns milky brown and can be seen on the dipstick, accumulating around the oil and radiator fill neck.

Aeration

Aeration or entrained air leads to cloudy compressable oil. This leads to foaming and metal-to-metal contact and increased bearing wear. The churning crankshaft of an overfilled engine will aerate the oil. Air is compressible and affects the oil's ability to lubricate and protect bearings.