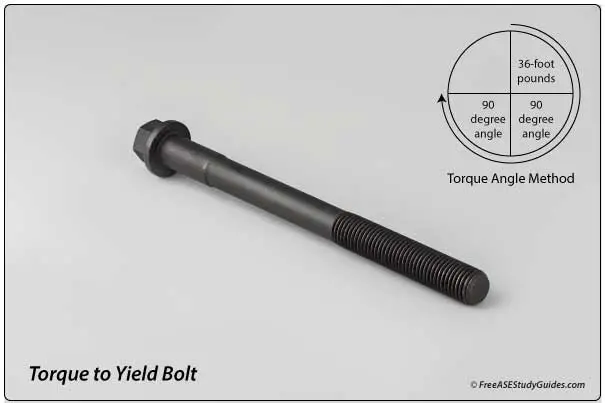

Torque to Yield Bolts

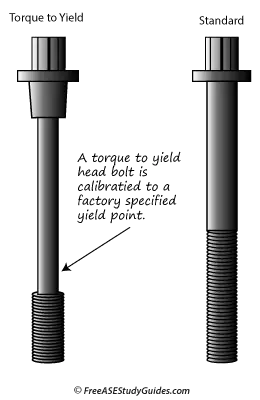

A standard bolt returns to its original reusable form and length when removed. All bolts have some elasticity and can stretch and return to their original reusable condition.

Most cylinder heads are aluminum; head gaskets are MLS (multi-layered steel) and mate to iron or aluminum engine blocks. Materials and conditions change. Iron and steel expand at different rates resulting in movement between the dissimilar metals. When heated, aluminum expands over twice the rate of iron.

The torque to yield bolt has a smaller shaft diameter and can adapt to the expansion of the aluminum cylinder head, applying a more constant clamping force. As a result, they are popular in modern vehicles. Many vehicles have these bolts in the engine and even the suspension.

Torque to Yield Bolt Failure

Cylinder head bolts are vital, and failure results in a head gasket leak. TTY bolts can stretch beyond their yield point; therefore, most manufacturers recommend discarding them after removal. The bolts can be expensive, but failure to replace them can lead to stripped threads, broken bolts (hard to remove), and a costly comeback (leaking cylinder head gasket).

Stretch Bolts

There are two terms related to this phenomenon. The first is elastic deformation, and the second is plastic deformation:

1. Elastic deformation:

Bolts are elastic and stretch to apply a clamping load. Elastic deformation is the amount of force or torque where the bolt has not changed shape or length. At this point, the bolt is reusable because it has not changed its shape.

2. Plastic deformation:

Plastic deformation is the point past elastic deformation where the bolt has changed its shape and length. At this point, the bolt cannot be reused and needs replacement.

Torque Angle Method

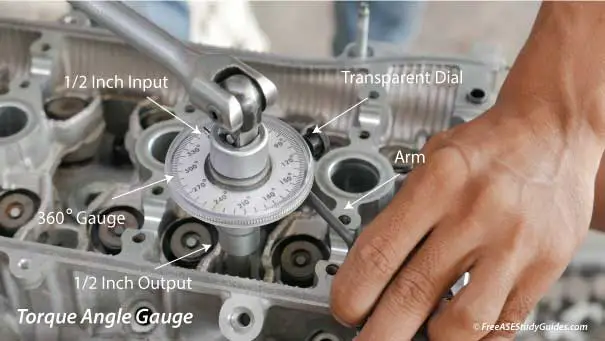

Torque to yield bolts are typically torqued to snug with a torque gauge and then angled. This process is known as the torque angle method. Check with the vehicle manufacturer for any special procedures.

For Example:

Torque the cylinder head bolts from the inside out, starting at the intake manifold to 36-foot pounds, and then apply two angled turns with a torque angle gauge.

- This first pass snugs the bolt without stretching it.

- The second pass would be a 90-degree angle or a quarter turn.

- The third pass would be another 90-degree angle.