Transmission Shift Solenoids

Shift solenoids are actuators used by electronically controlled transmissions to control fluid flow.

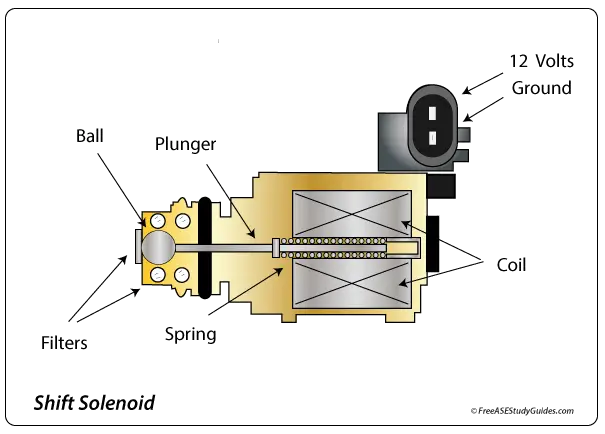

Standard on/off solenoids have only two positions, either on or off. They consist of a spring-loaded plunger wrapped with a coil of wire that, when energized, draws the plunger inwards, either opening or closing a hydraulic circuit. When power is removed from the solenoid, the plunger is pushed by a spring to its normal position. Depending on the transmission, a solenoid can be normally open or closed.

Shift solenoids can be controlled by the circuit's ground or power side. On some transmissions (usually older), the solenoid is powered by a 12 V signal from the (TCM) transmission control module. Most transmissions control the solenoid from the ground side by pulsing the ground circuit on and off.

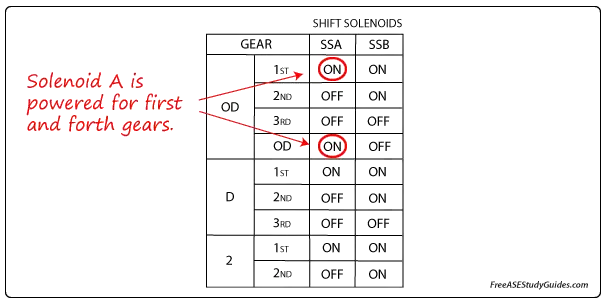

Solenoid Application Chart

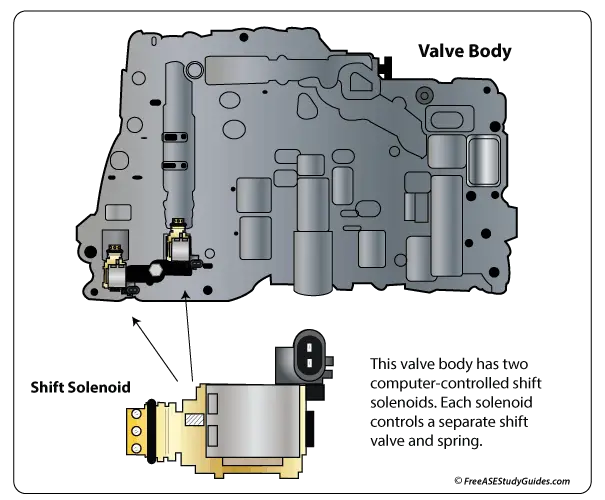

Transmission solenoids are electro-hydraulic actuators that the TCM uses to control the flow of pressurized transmission fluid throughout the transmission. The solenoid application chart above is used to diagnose automatic transmission shift problems.

The chart reveals that activating shift solenoid A causes the transmission to shift into the first and fourth gears. The TCM powers solenoid B to shift into first and second. The TCM activates shift solenoids based on inputs from both engine and transmission sensors.

Shift Solenoid Diagnosis

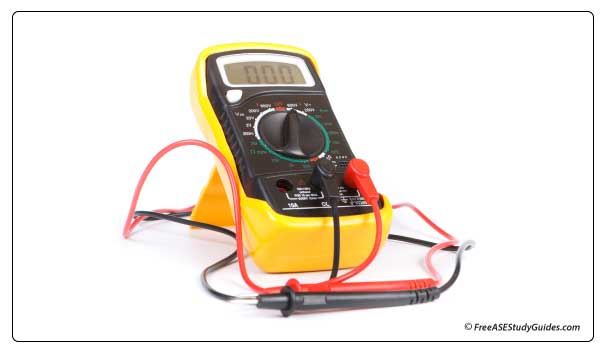

The diagnosis begins with a scanner and a DMM. A scanner identifies the faulty solenoid or it's a related circuit. If the scanner describes a high-power circuit code, check the solenoid's ground side and follow the flow chart. If there's a low power code, use the DMM to check the solenoid's power feed. Automatic transmissions use two or more solenoids and power them on and off at different times to achieve different gears.

Automatic transmissions have an internal harness connecting the transmission's sensors and solenoids to an outside connector. Locate the correct pins on the connector to test electrical components and internal circuits with a multimeter. Check the vehicle's manufacturer for TSB’s, specifications, pin location, and special procedures.