(EPC) Electronic Pressure Control

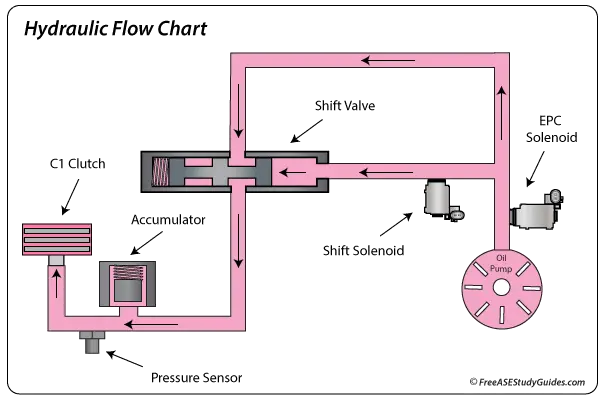

Today's electronic transmissions use a control module to control transmission line pressure, shift timing, and quality. It receives inputs from sensors like the MAF or MAP, VSS, and ECT and then compares them to the information stored in its memory. It then pulses this solenoid on and off to raise or lower line pressure according to demand.

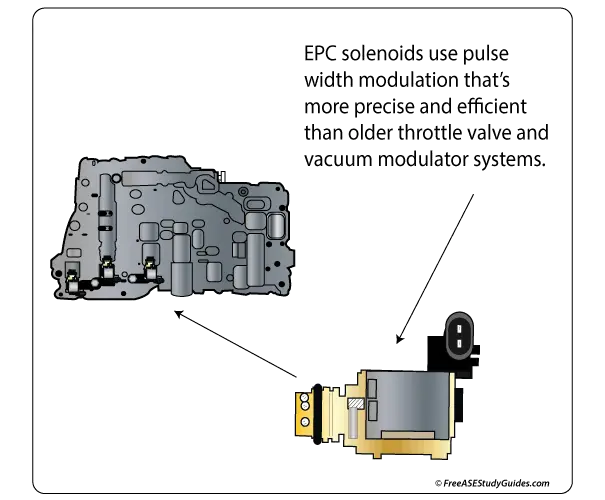

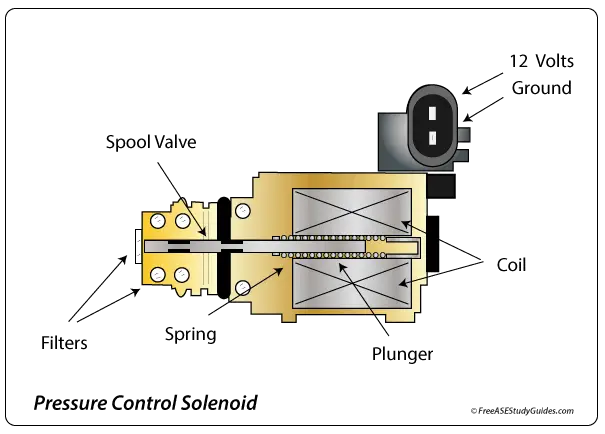

The EPC controls a pressure-regulating spool valve and spring that holds or releases fluid pressure, typically back to the transmission's sump. It's a variable force solenoid that changes at around 32 Hz (32 times per second). It has more precise control than a conventional hydraulic pressure control system. The EPC system is more efficient and helps the engine stay within its powerband by promptly changing system pressures.

The system uses spring pressure to close the valve, providing maximum system pressure. As the module increases current to the solenoid's windings, the EPC plunger and spool valve move, opening the exhaust port and reducing line pressure.

EPC Duty Cycle

High line pressure is often the result of an unplugged or damaged circuit leading to the solenoid. The control module pulses the solenoid longer with a high-duty cycle to reduce line pressure (~70-80% on-time) and a shorter duty cycle to increase line pressure. The longer it's on, the lower the pressure.

EPC Solenoid Testing

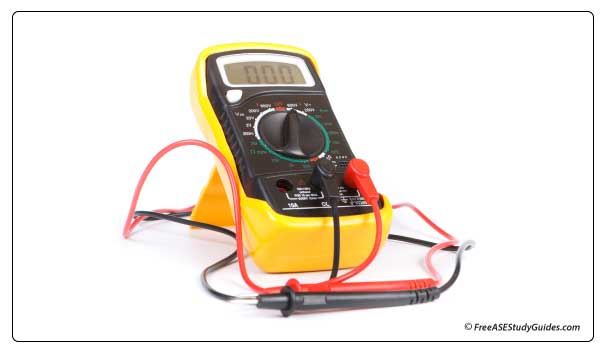

If the vehicle's line pressure is above or below specifications, the EPC solenoid and its circuit can be tested and diagnosed with a scanner and an ohmmeter. Check with the vehicle manufacturer for the type of system used and any special testing procedures. Always use a high-impedance multimeter when testing sensitive computer circuits.