Torque Converter Lockup Clutch

The torque converter is a fluid coupling and torque multiplier that enables a vehicle with an automatic transmission to idle in gear at rest. They are inefficient because much of the engine's kinetic energy is lost and converted into thermal or heat energy, particularly at stoplights. The transmission fluid cooler releases this heat into the engine's cooling system.

As vehicle speed increases, the impeller (the pump) spins and forces transmission fluid against the turbine blades with enough velocity to turn the transmission's input/turbine shaft. Engaging the lockup clutch at the right time cools the transmission fluid and improves fuel efficiency.

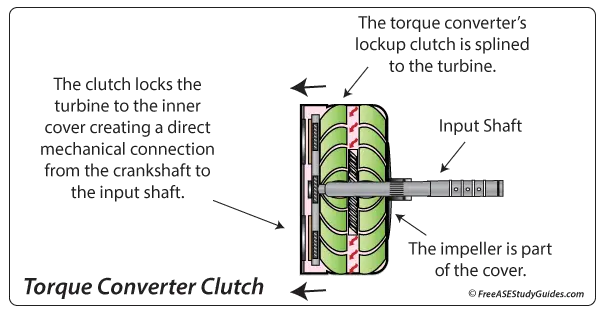

The lockup clutch creates a mechanical link between the engine and the transmission. This connection occurs during the coupling phase when the turbine spins at about 90% of the impeller's speed.

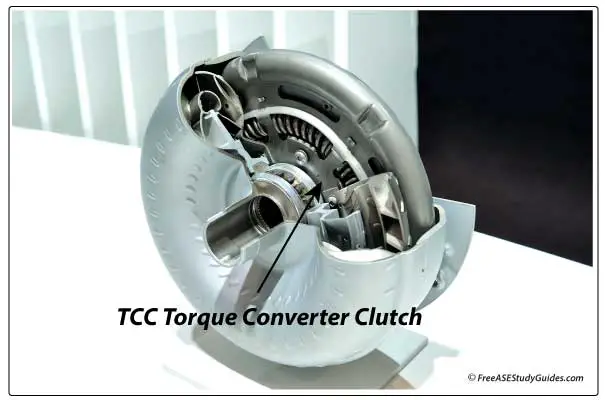

The clutch is splined to the turbine so that, when pressed against the inner cover, it directly connects the crankshaft flange to the transmission's input shaft. It has a circle of friction material and torsional springs to dampen the vibrations created by the crankshaft.

The TCC Solenoid

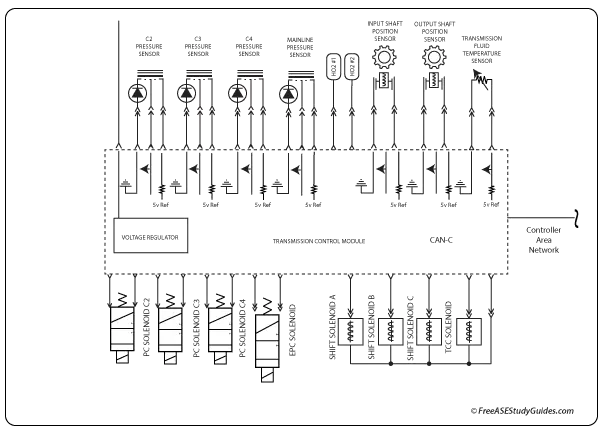

Transmission control modules use internal sensors and sensor signals over the network (CAN) to activate the TCC (torque converter clutch) solenoid. The TCM also controls shift and pressure control solenoids based on inputs from both engine and transmission sensors.

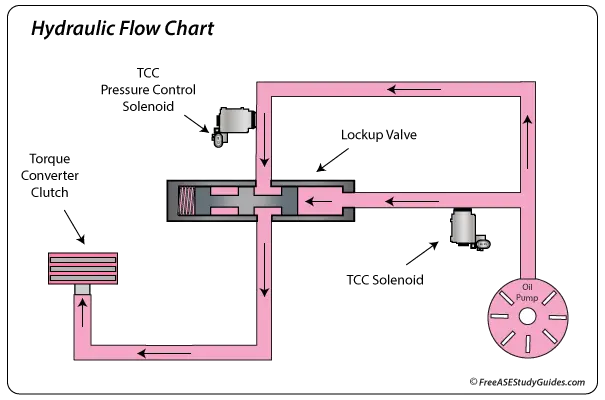

The clutch does not engage in first or reverse gear because doing so will cause the vehicle to stall. Today's vehicle can partially engage the clutch using PWM (pulse width modulation).

When the TCM activates the TCC, the TCC valve moves to the left. This action opens the passage from the pulse width modulated pressure control solenoid to the torque converter's clutch. This variable pressure softens the transmission clutch application. PWM provides a better feel by gradually increasing the duty cycle for a partial or a smooth to full clutch application.