Measuring Brake Rotors

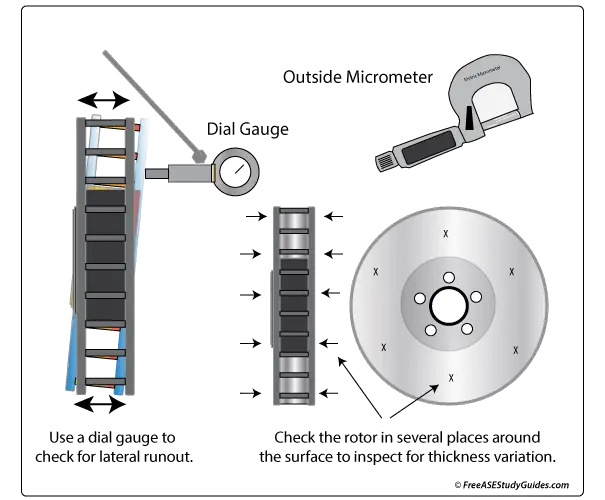

Take lateral runout and parallelism measurements before discarding or machining a brake rotor. In time and from excessive heat, a brake rotor warps and becomes distorted, causing vibration while braking. Use a dial gauge to measure a rotor’s lateral runout. Use an outside micrometer to measure a rotor for thickness variation or parallelism.

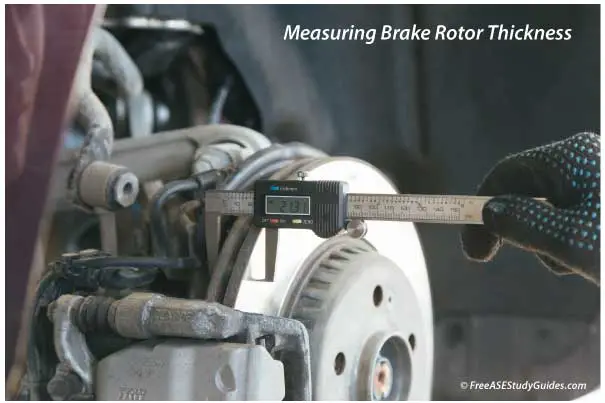

Measure the thickness of the rotor with an outside micrometer in several places. A thick rotor can absorb and store more heat than a thinner one.

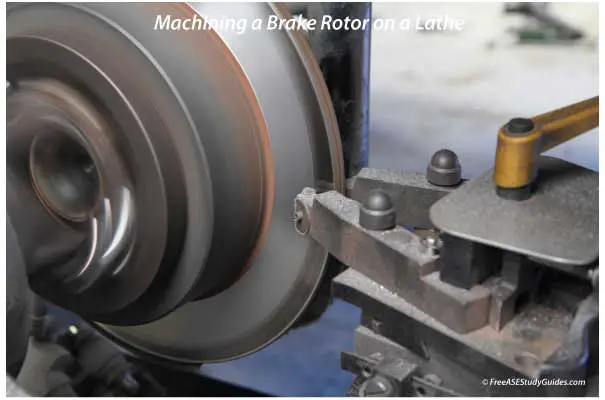

When a hot rotor cools quickly, like sitting in a deep puddle too long, it may not return to its original form and begin to distort or warp. This is especially true with single-bladed, non-vented rotors found on the rear brake units of many vehicles today. They can also develop dark pad deposits called cementite, which is harder than the surface of the rotor and left behind when machining. Replace a rotor with cementite deposits.