Piston Ring Groove Clearance

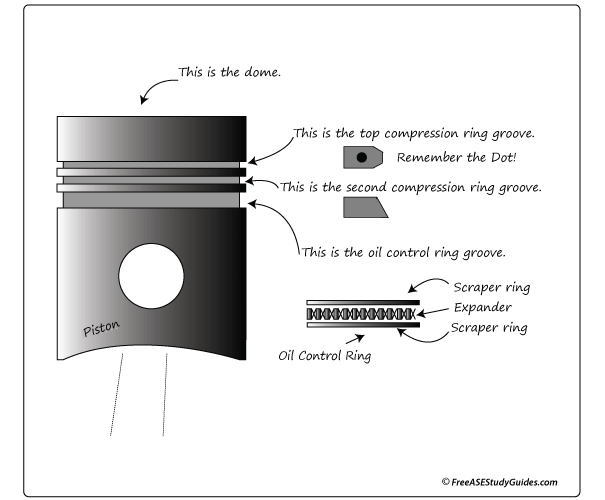

Pistons are grooved to fit rings that seal the cylinder's compression and allow for lubrication of the cylinder walls. Piston rings come in a set. There are two compression rings. The top ring is affected by the most cylinder compression pressures. The second compression ring reinforces the top ring. The third ring down is the oil ring. It controls lubrication between the piston and cylinder bore.

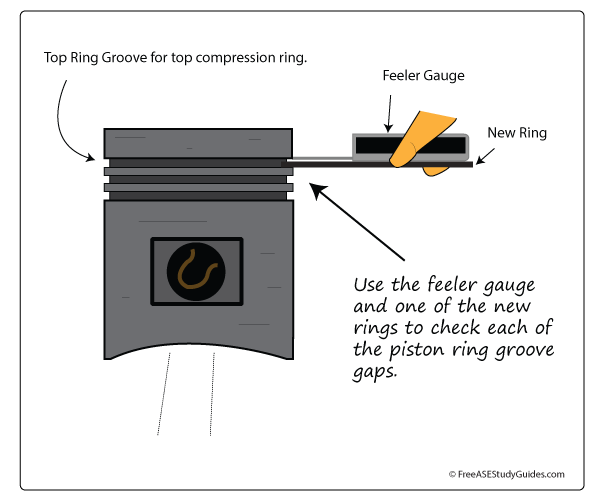

Place the new ring into the top piston groove, and then place a feeler gauge into the gap between the new ring and the upper land. Move around the pistons groove and obtain a few measurements. Compare this reading to specifications. If this reading is too much and the gap is too large, the piston must be replaced. The top ring takes the most compression. It causes the ring to slap against and wear the lands in the piston groove.

Tapered Rings

Tapered rings must be installed in the groove correctly, with the dot up. Check with the manufacturer's specifications. If installed incorrectly, the ring would end up scrapping the oil up into the cylinder, instead of down into the case.