Turbo Charger: Controls

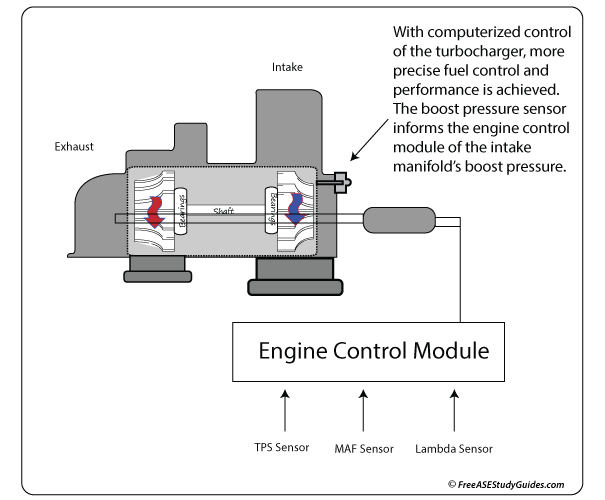

Manufacturers install small turbocharged engines in their vehicles, providing extra power and saving on engine weight and size. In addition, they have improved performance with the use of computer controls. As a result, they have increased fuel mileage and horsepower, especially during initial acceleration.

Boost Pressure Sensor

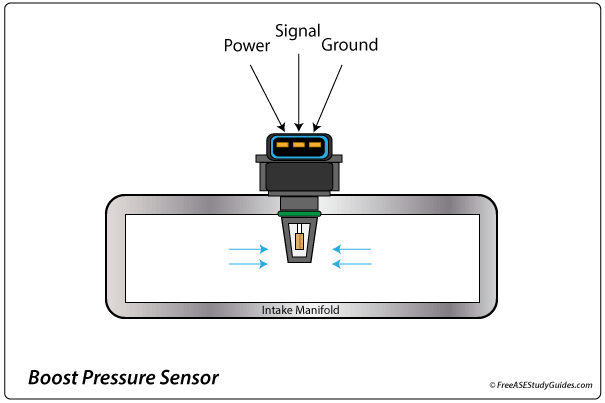

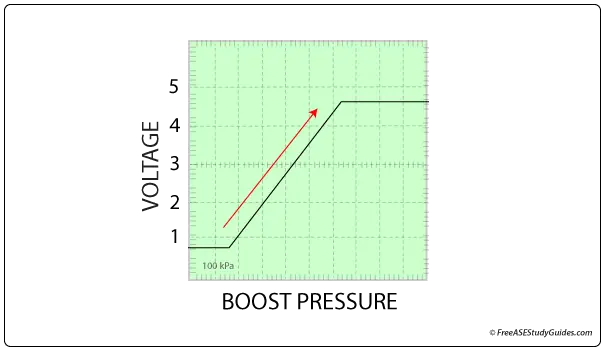

The ECM monitors boost pressure, throttle angle, airflow, and more. Turbocharged and supercharged engines use (BPS) boost pressure sensors, usually with MAP and MAF sensors, to monitor intake manifold vacuum and boost pressure. The boost pressure sensor monitors positive or boost pressure with a probe inside the intake manifold. It receives a (5-Volt) reference signal from the ECM. The sensor's voltage signal to the ECM starts low and increases as boost pressure increases.

The ECM uses the signal from the MAP sensor to check the boost pressure sensor's operation. It will illuminate the check engine light and set a fault code if the sensor fails or is out of range. The ECM is making air-fuel mixture decisions based on input from this sensor. A faulty BPS results in poor acceleration, fuel mileage, and engine performance.

The sensor's probe can become contaminated with carbon and tarnish. Sometimes, the tip can be cleaned like a MAF or MAP sensor. Carefully spray MAF sensor cleaner to remove any carbon corrupting the sensor's signal.