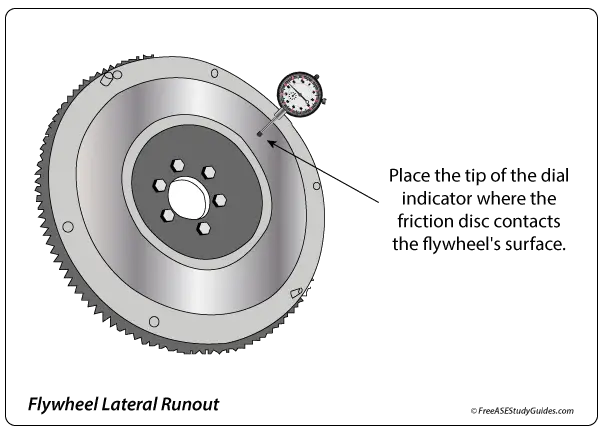

Flywheel Lateral Runout

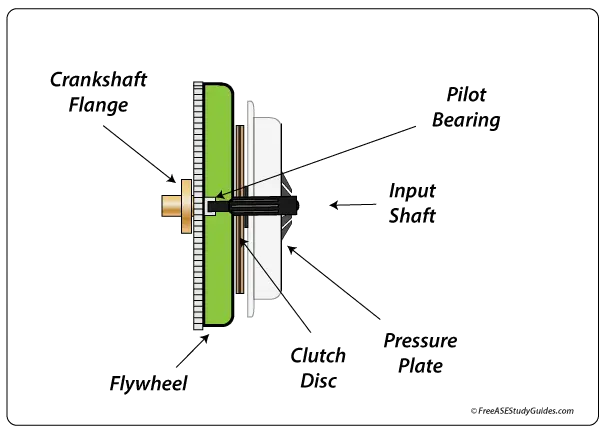

Flywheels provide a clamping surface for the clutch disc, absorb heat, and dampen engine pulses and vibrations before they pass to the transmission. Inspected the flywheel's surface for scoring, wear, and lateral runout whenever replacing the vehicle's clutch disc.

To check the lateral runout on a conventional flywheel, place the tip of the dial indicator on the flywheel's surface and rotate it with a turning tool or turn the crankshaft bolt with a socket and ratchet. The difference between the lowest and highest reading is the lateral runout.

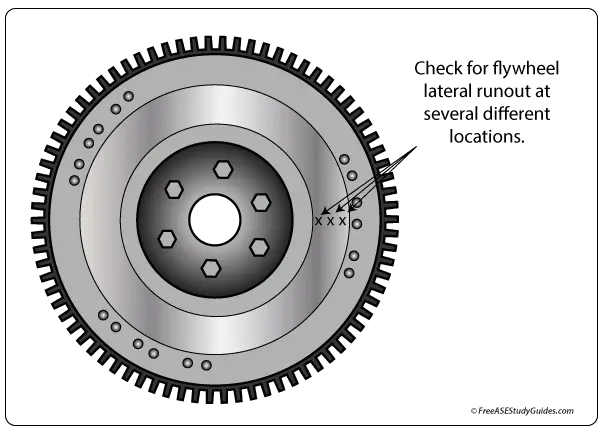

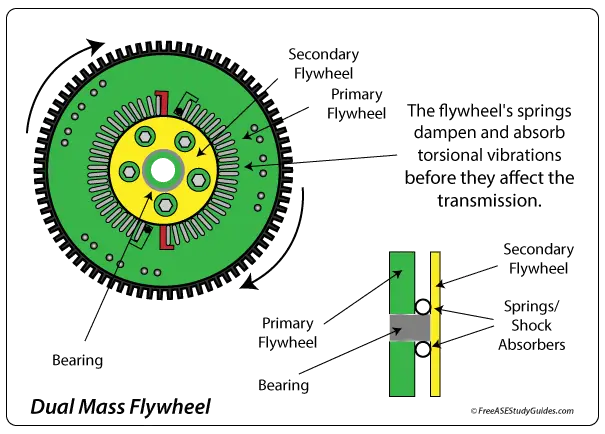

Check for lateral runout in several spots and compare the readings to the manufacturer's specifications. Most imperfections can be removed with light sanding. Not all flywheels are easily resurfaced. Some of today's vehicles contain dual-mass flywheels. These flywheels have springs that function similarly to the torsional springs in a clutch friction disc.

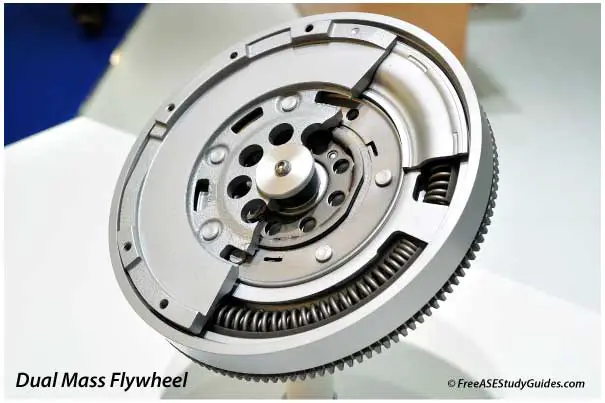

Dual Mass Flywheels

A dual-mass flywheel contains two plates, a bearing, and springs that absorb torsional vibrations. Today's powerful diesel and four-cylinder engines create oscillating vibrations that pass through the clutch and transmission. A dual-mass flywheel significantly reduces these vibrations.

Dual-mass flywheels are often replaced instead of resurfaced. A new dual-mass flywheel has a little movement between the plates; as it wears, this play increases. Check with the flywheels manufacturer; typically, if the left-to-right play is more than an inch, it must be replaced. The springs and bearings begin to wear, resulting in a driveline vibration most noticeable at high speeds.

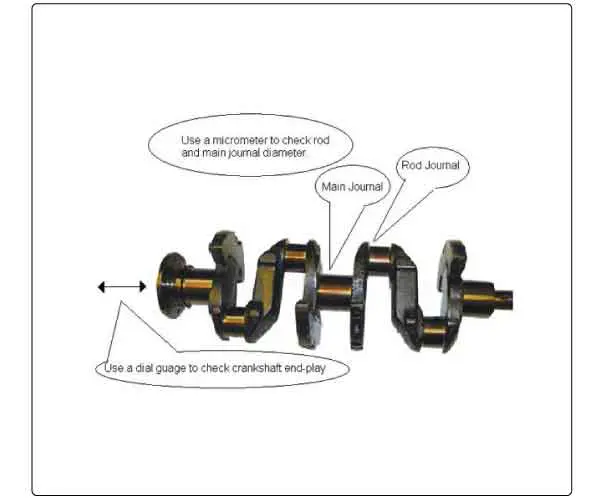

Check Crankshaft Endplay

Check crankshaft endplay by placing the tip of the dial gauge on the flywheel's surface. Push the flywheel all the way in towards the engine block and record the reading, then pull it all the way out and record the reading. The difference between the two readings is the crankshaft endplay.