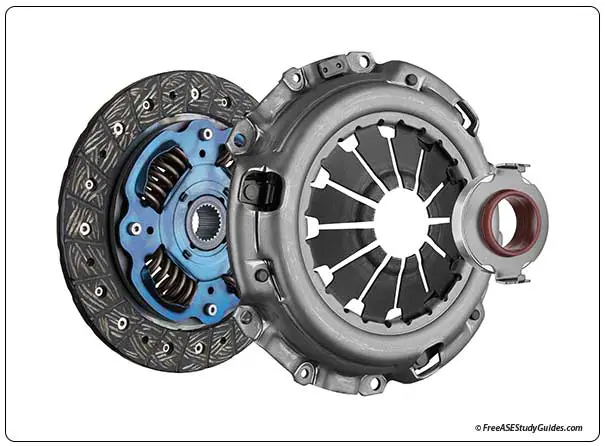

Pressure Plates, Clutch Discs, and Clutch Kits

Manual transmissions and transaxles use a clutch to engage and disengage power flow from the engine to the transmission's input shaft. The clutch is normally engaged; depressing the pedal releases the clutch, enabling the driver to change gears.

The clutch disc contains friction material and torsion springs. Sandwiched between the flywheel and the pressure plate and splined to the input shaft, it transmits power from the flywheel to the vehicle's drivetrain.

A worn clutch begins to slip in gear, grab, and release, resulting in harsh shifting and clutch chatter. Clutch chatter is different than clutch slippage. Clutch chatter begins when the clutch is applied and goes away after fully engaging. Clutch slippage is the clutch disk's continued spinning without full engagement. Replacing a clutch is considered heavy line and typically involves separating the engine from the transmission.

Pressure plates contain springs that keep the clutch engaged. Most contain a single diaphragm spring like the one in the illustration above. Depressing the fingers of the diaphragm releases the plate, allowing the clutch disc to spin freely.

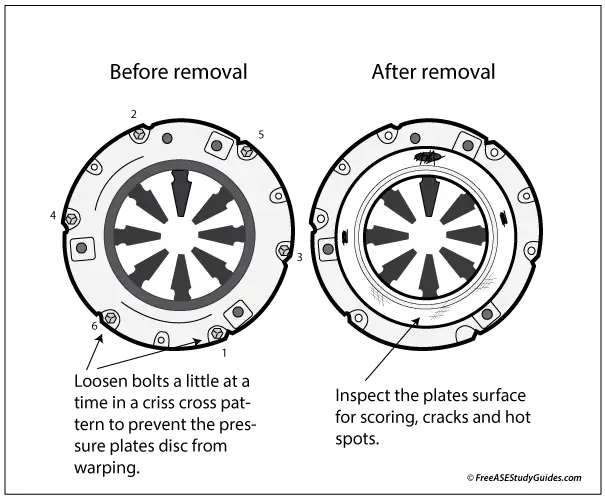

Remove the pressure plate's bolts a few turns at a time and in a crisscross pattern. Failure to do so can result in a warped pressure plate. Inspect the pressure plate for warping and hot spots. The plate and the release bearing are paired when replacing a worn clutch disc.