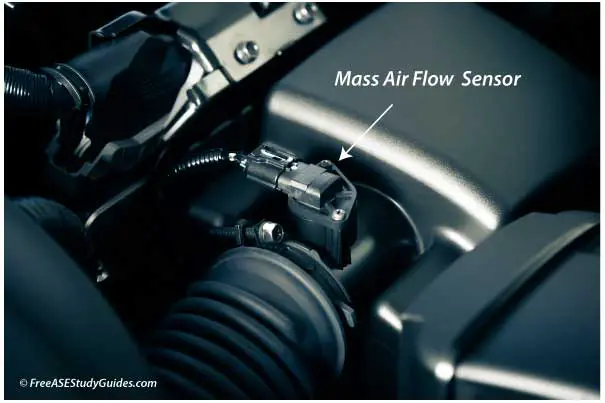

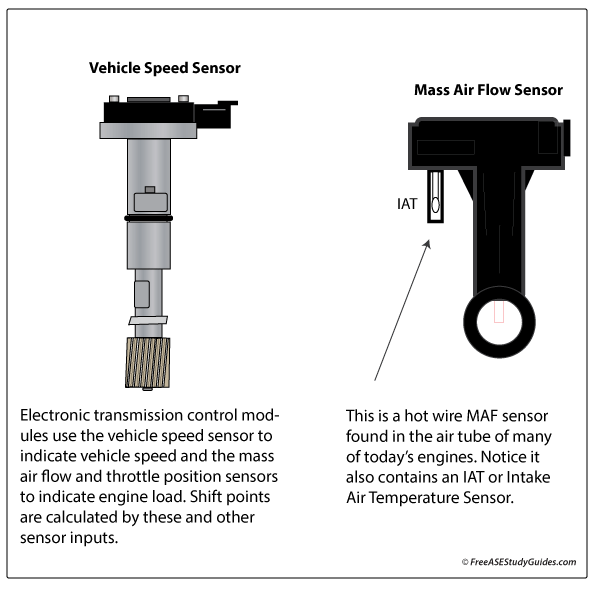

Mass Air Flow Sensor

MAF (Mass Air Flow) sensors measure the volume of air passing through the air tube. There are several types found on vehicles today. These include the cold wire, heated wire, Karmen Vortex, and vane-type MAF sensors. The vane sensor is also known as an airflow meter.

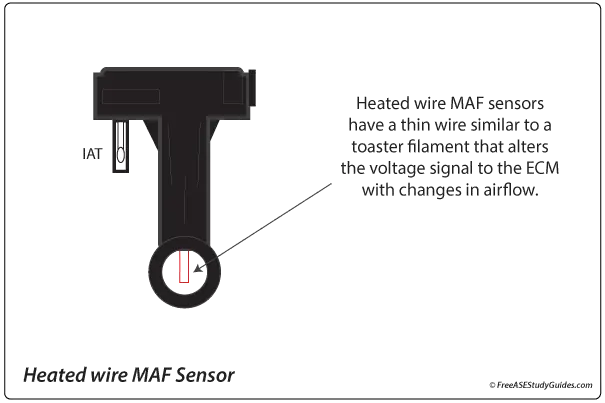

A hot wire MAF sensor has a heated filament like a toaster. The sensor's resistance changes or decreases as cool air passes by the filament. The increase in current to maintain the sensor's heat is converted to a voltage signal and sent to the ECM to adjust the air-fuel ratio.

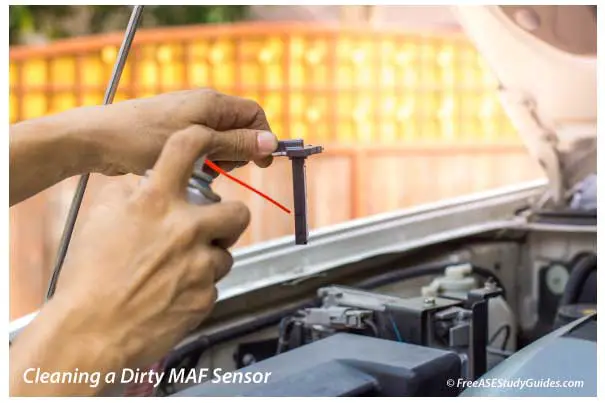

Because this heated filament gets dirty from time and wear, a cleaning may return the MAF to its normal operating condition. There are products designed to clean a dirty MAF sensor on the market, and the process usually only takes a few minutes. Remove the sensor, carefully spray the filament until it is clean, and re-install it.

The OBDII Fuel Trim Monitor

Utilize the OBDII fuel trim monitor. The coating produces a slightly rich air-fuel ratio at idle and low speeds and a slightly lean signal during acceleration.

Symptoms of a dirty MAF sensor include loss of power, hesitation, stumble, and reduced gas mileage. A dirty MAF signals the ECM to add fuel at low speeds, resulting in a slightly positive (LTFT) Long Term Fuel Trim. Excessive positive LTFT (+ 10%) indicates a persistent lean fuel condition. The ECM will illuminate the check engine light when the fuel trim exceeds 25% in either direction.

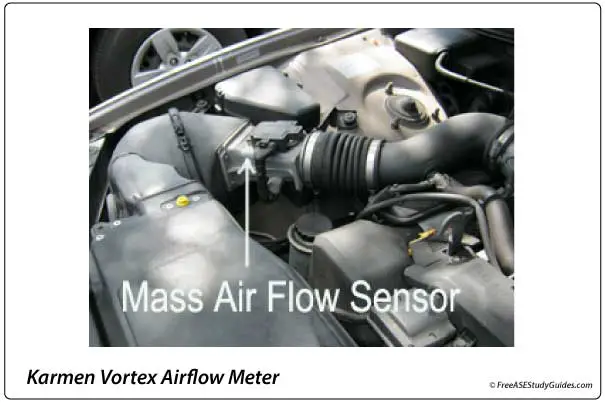

The Karmen Vortex airflow meter does the same thing but creates a vortex captured by a photocoupler and a mirror. This signal is converted to a voltage signal to be sent to and interpreted by the ECM.

A vane type MAF sensor uses a paddle or door that moves as the air rushes through the air tube. This type of sensor utilizes a potentiometer (variable resistor) to send a variable or changing voltage signal to the ECM in proportion to air volume.

A cold wire MAF sensor uses thin metal strips that vibrate as the air passes through the air tube. This vibration changes the frequency of the signal sent to the ECM.

The MAF and Electronic Transmissions

The MAF sensor provides the ECM and TCM with valuable information regarding engine load. It is calculated by multiplying air density by air volume. The transmission control unit uses this information for shift control. A mass air flow sensor left unplugged, faulty, or dirty will dramatically affect a vehicle's shift control.