Ring and Pinion Gear Set

Differential ring and pinion gears, bearings, and all associated parts must be cleaned thoroughly before inspecting. Check the gears for unusual wear patterns, scoring, chipped, or damaged teeth.

Ring and pinion gears come as a set. Replace both of them if one of them is damaged, out of specs, or worn. When a vehicle pulls a heavy load, the pinion gear tends to ride on the outer portion of the ring gear. It causes excessive scoring, evident on the outer edges of the ring gear.

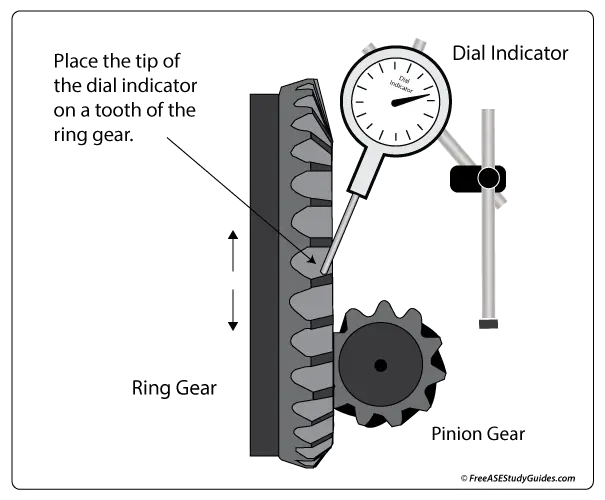

Gearsets without timing marks are considered hunter sets. Typical ring and pinion gears have notches and painted marks for proper alignment. Incorrect installation results in noise and premature wear. Ring gear runout is the amount of warpage in the ring gear. Check for ring gear warpage with a dial indicator mounted on the differential case. If the ring gear is warped, finding the cause is important. Though this warpage is typically due to wear, the differential case mounting surface should be checked with a dial gauge. Worn side bearings can cause a ring gear to warp.

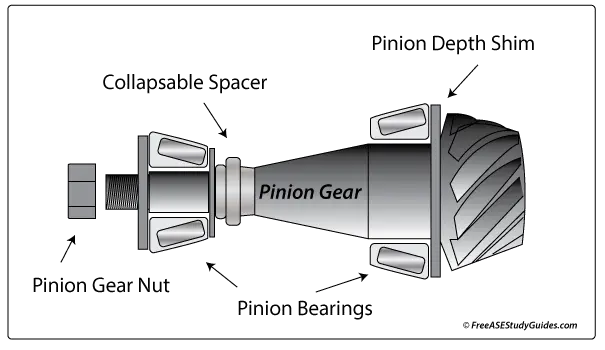

Special depth micrometers achieve proper pinion gear depth. The pinion gear depth is adjusted using shims placed in the housing. This adjustment determines the mesh of the pinion into the ring gear. Adding shims increases the depth of the pinion shaft, and removing shims decreases the depth.