Flywheel Inspection

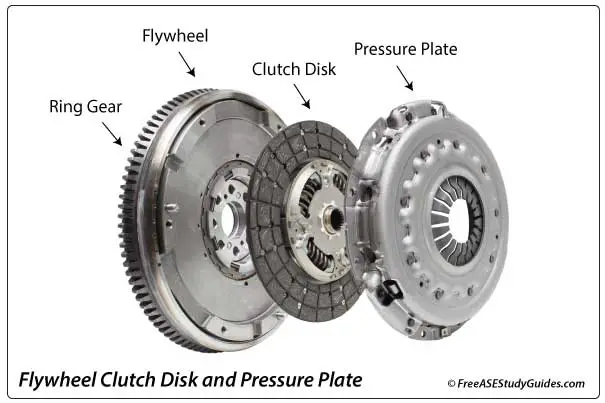

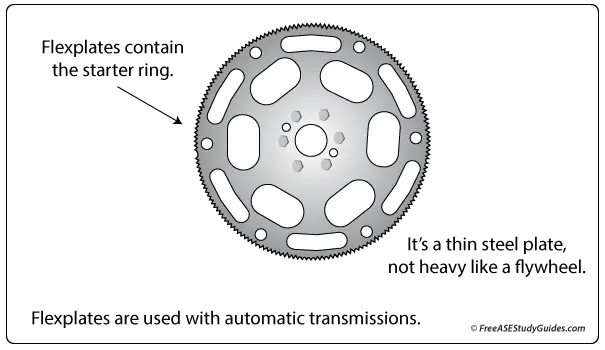

Inspect the flexplate or flywheel for damage and wear after engine removal. Flexplates are found on vehicles equipped with automatic transmissions. Flywheels are found on vehicles equipped with manual transmissions.

Automatic transmissions do not have pressure plates, friction discs, or flywheels. The ring gear of an automatic transmission is attached to the flexplate. When a flexplate wears, it develops cracks around the bolt holes. Replace the flexplate if the bolt holes are elongated or the teeth on the ring gear are chipped or worn.

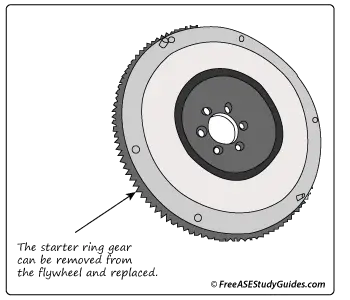

If the ring gear on a flywheel is damaged, it can often be removed and replaced. The flywheel can be resurfaced if the surface area has light surface cracks or scoring. Resurfacing a flywheel ensures that it has the proper flatness and smooth finish. The surface area must be smooth and not warped. Warpage reduces the contact area of the flywheel, allowing it to slip. Slipping causes excessive heat, hotspots, and glazing.

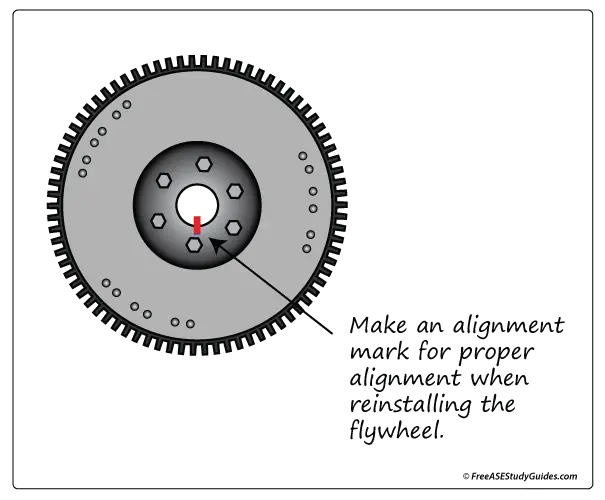

Whenever removing a flywheel from an engine's crankshaft, mark its position to the crankshaft. Replace the flywheel in this same position during reassembly. This process ensures the balance of the flywheel to the engine. An unbalanced flywheel can cause excessive drivetrain vibration.