Driveshaft Runout

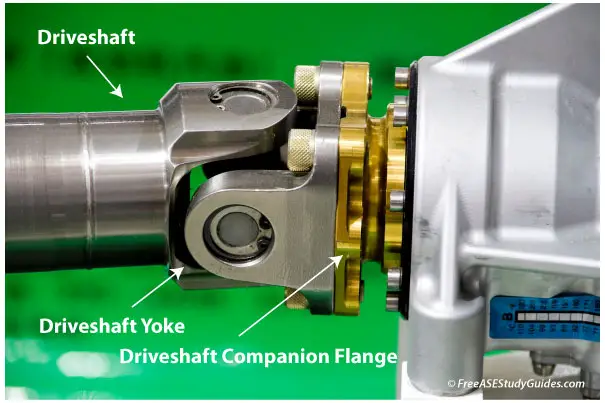

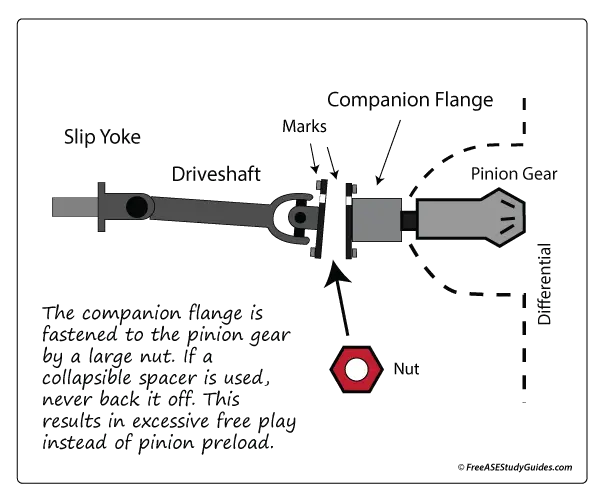

This question reminds us of the many things that can cause a driveline vibration. The driveshaft companion flange connects the driveshaft to the differential pinion gear. Inspect the flange for any damage or looseness if a driveshaft vibration is suspected. Always mark the companion flange to the driveshaft flange before removing the driveshaft. This mark ensures that the two surfaces are installed in their original positions.

If there was a vibration during the test drive and the pinion seal leaks, suspect a bad collapsible spacer. Never back off a collapsible spacer once installed. These spacers can be used only once. That's why it's important to torque this nut in increments, checking the setting frequently with an inch-pound torque wrench.

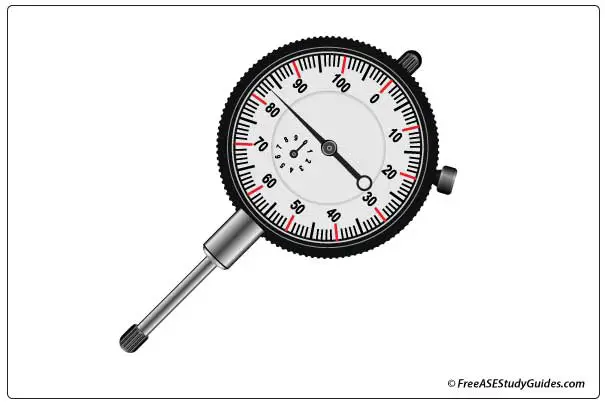

Check the flange for runout by placing a dial gauge on the flange surface and rotating the flange. Little tolerance is allowed. Check for specifications before proceeding.

To check the driveshaft for excessive runout, shut down the engine and make sure the shaft is not rotating. Place a dial gauge at the center and both ends of the driveshaft and turn it with your hand. Compare the measurements taken with the manufacturer's specifications before considering replacement. Replace a damaged or bent driveshaft.