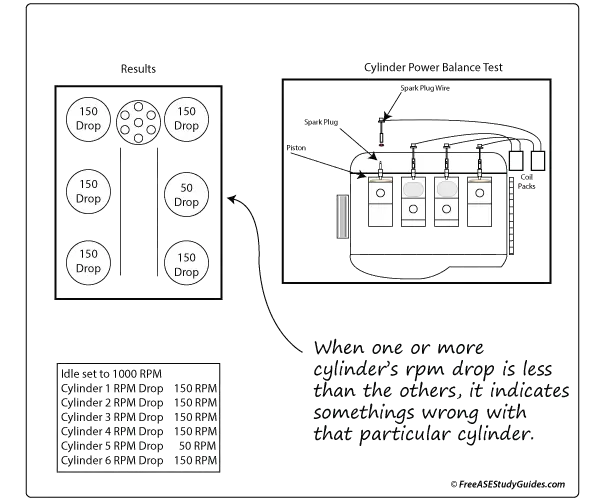

Cylinder Power Balance Test

A cylinder power balance test tests each cylinder's effectiveness compared to the others. A weak cylinder typically results from ignition, fuel delivery, a vacuum leak, or a mechanical problem, such as a faulty valve or worn piston rings. In addition, a faulty head gasket, cracked cylinder head, or block will cause an RPM drop on adjacent cylinders.

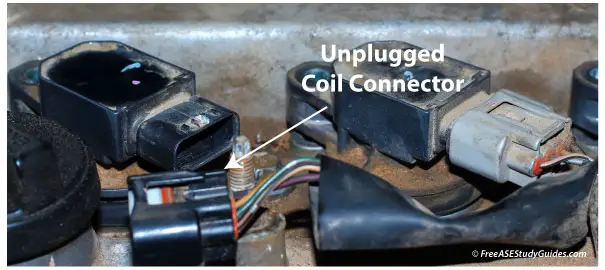

Removing a plug boot from its plug to cut a cylinder was standard procedure for many years. The problem is that a prolonged open in the secondary ignition system may cause damage to the coil or ignition module, and intentionally dumping raw fuel into the catalytic converter is ill-advised.

Check the manufacturer's specifications before proceeding, and remember safety first. For example, sometimes a sensor, like an O2 sensor, will need to be disconnected so the computer will not try to compensate for the sudden change in conditions.

Test each cylinder at a speed of around (800-1000 RPM). Notice the drop in RPM while disabling the cylinder. If it is inconsistent with the others, that cylinder has a problem. An engine analyzer tests each cylinder and then compares the results; if no engine analyzer is available, record the test results with a pencil and paper.

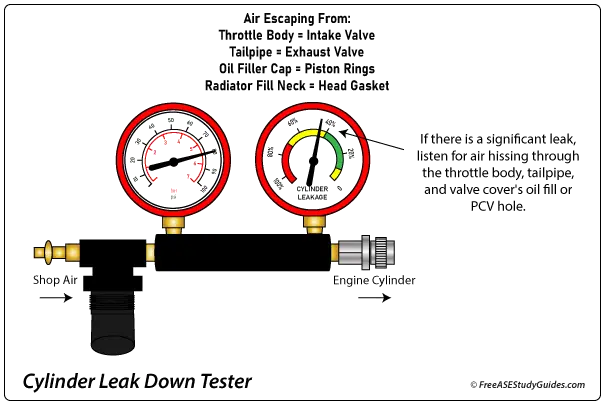

Cylinder Leak-down Test

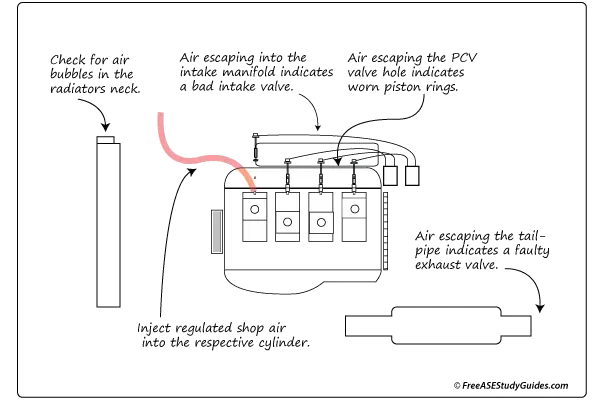

Performed a cylinder leakage or leak-down test after a cylinder balance and a cylinder pressure test verified a cylinder problem. It shows the percentage of leakage and pinpoints the part causing the compression leak.

Listen for air hissing through the throttle body or carburetor. This sound indicates a problem with an intake valve. It allows compression to seep past the valve and its corresponding seat. Next, listen for air escaping through the tailpipe, showing a problem with a worn or burned exhaust valve. Air escaping through the oil fill cap indicates worn piston rings. Bubbles seen in the radiator neck indicate a leaking head gasket.