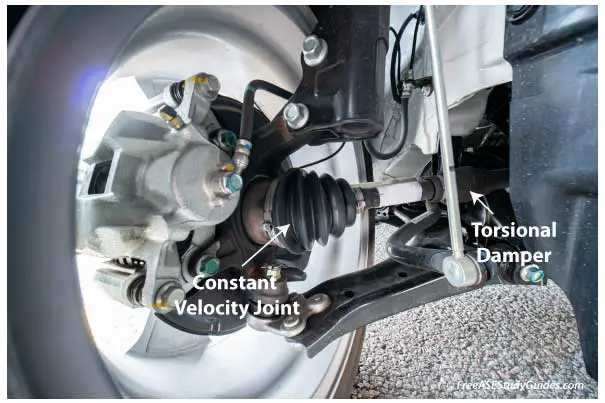

Constant Velocity Joints

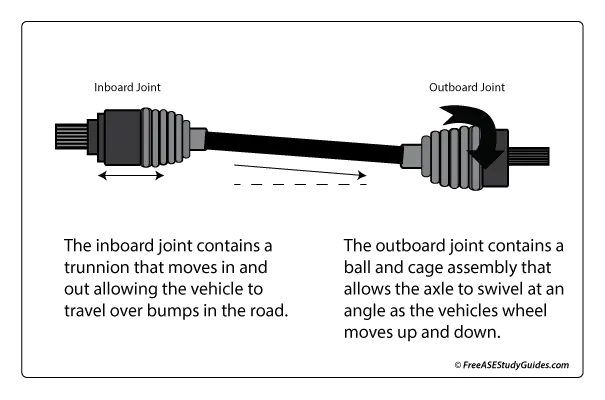

Front-wheel drive axles have constant velocity joints or CV joints on their inboard and outboard ends. They allow for movement as the wheel turns and the vehicle travels over bumps in the road. As the joint wears or loses vital lubrication, it becomes noisy.

The most common problem is the rubber boot that protects the joint wears, breaks open, and loses its lubrication. If the joint is still good, boot kits are available to replace the boot and lubrication.

Listening to the customer and road-testing the vehicle before performing a visual inspection is important. Find out if the noise occurs while accelerating or while turning. During the road test, listen for familiar noises like worn wheel bearings that produce a growling sound that increases with vehicle speed.

Inboard joint: A worn or faulty inboard joint makes its most noise while accelerating and decelerating. This is often due to a lack of lubrication in the tripod bearings that must slide smoothly in and out of the encasing. They will also make a vibration around 40-50 mph, similar to an out-of-balance tire. Most of these joints can be serviced by removing the snap ring from the end of the axle shaft and tapping on the tripod case with a soft hammer.

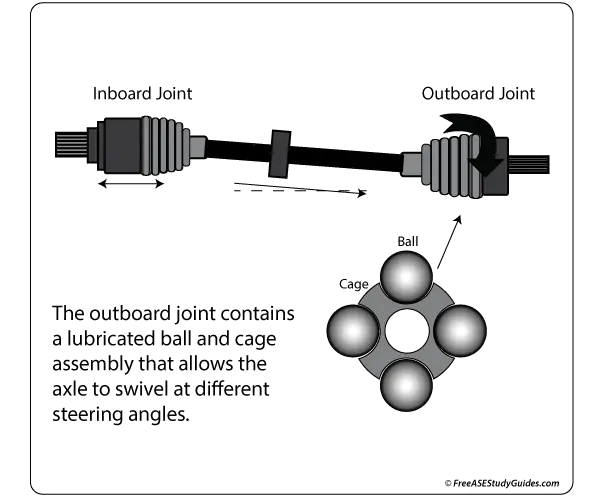

Outboard CV-joint: A worn or faulty outboard CV-joint makes its most noise while cornering. This is even more noticeable in reverse. Always use caution and pay attention while road testing a vehicle, and avoid getting so engrossed in diagnosis that you cause an accident.

Turn the wheel left and right while listening for a clicking noise while traveling forward. A faulty joint will make the most noise when it is inside the turn. These joints can make a squeaky noise while traveling in a straight line but will make the most while turning. They consist of large ball bearings encased in a cage that allows the joint to rotate in circles as the wheel is turned.