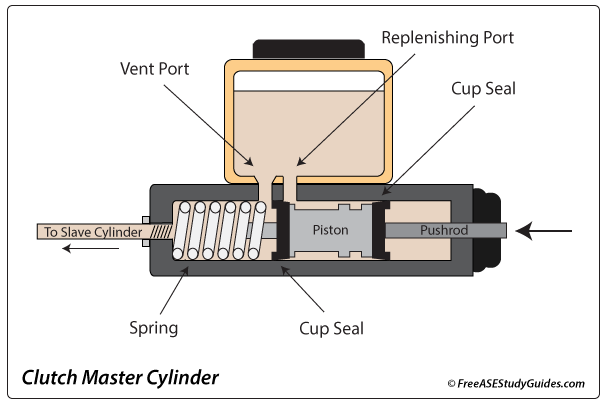

Clutch Master Cylinder

A clutch master cylinder uses a single-piston that works similarly to a brake master cylinder. The piston contains cup seals that move fluid through a smooth bore to create hydraulic pressure. The pressure is transferred through a line to the slave cylinder. Clutch master cylinders develop leaks both internally and externally. Check for an external leak on the floorboard behind the clutch pedal or the engine compartment's firewall. If there is a loss of pressure after the clutch is applied, and there are no external leaks, suspect an internal leak. Internal leaks are caused by cup seal wear or fluid contamination.

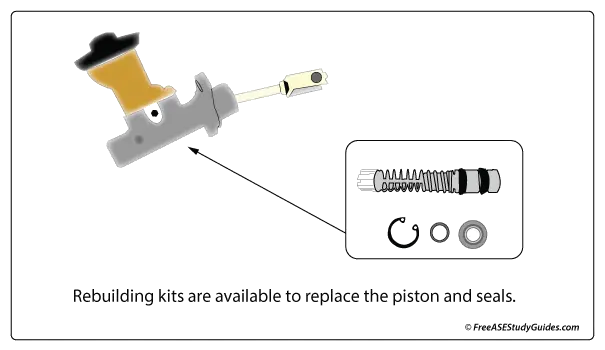

When a leak or binding occurs, it will be necessary to rebuild or replace the master cylinder. Rebuilding kits are available for most clutch master cylinders. If it is a cast-iron cylinder, the bore should be honed and cleaned with brake fluid before replacing the internal parts. An aluminum master cylinder should be cleaned entirely with brake fluid but not honed before installation. This is because the hone will remove the coating used to seal and harden the cylinder's aluminum bore.