Brake Lines and Hoses

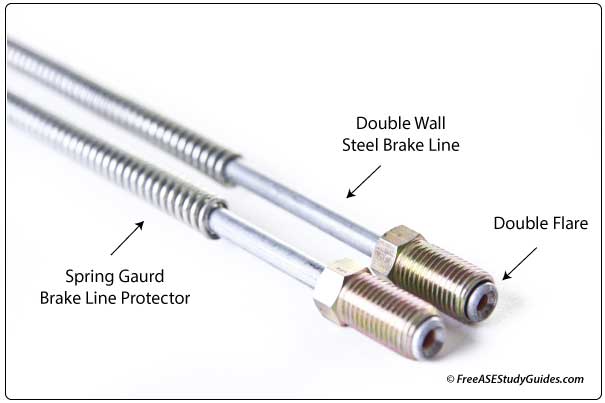

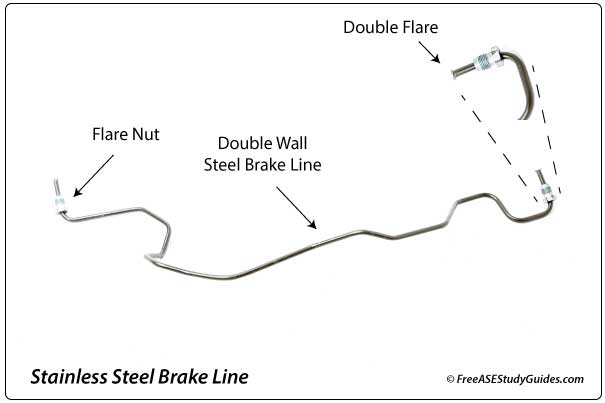

Brake lines are typically double-wall steel tubing (no seams) with one of two standard flares on each end. These are the double flare and the ISO flare. Manufacturers install double-walled steel brake lines because they can withstand the high pressure and vibration of automotive brake systems.

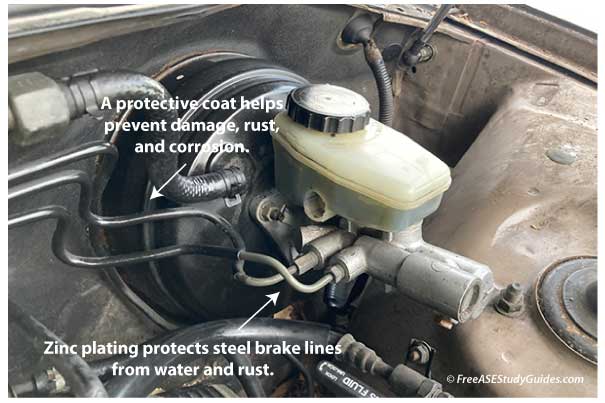

Most brake lines are seamless and contain a zinc, tin, or epoxy coating capable of resisting rust and corrosion. Rust is a big problem with brake lines. Therefore, most manufacturers install coated brake lines from the factory for corrosion and rust protection. PVF (polyvinyl fluoride) brake line lasts much longer and is more rust-resistant than standard stainless steel.

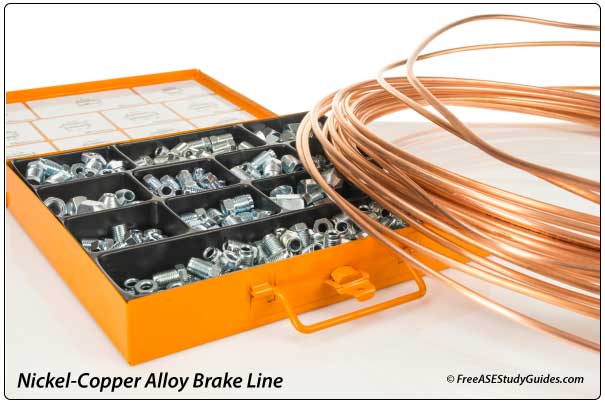

Bending and flaring the ends of the brake line takes patience and practice. Some manufacturers and fabricators use a DOT-approved copper-nickel alloy brake line, which is a little weaker but more flexible and easy to bend and flare.

Copper (100% Copper) tubing found at the hardware store cannot withstand the hydraulic pressure in automotive brake systems. Never install a brake line that the vehicle manufacturer does not approve for service.

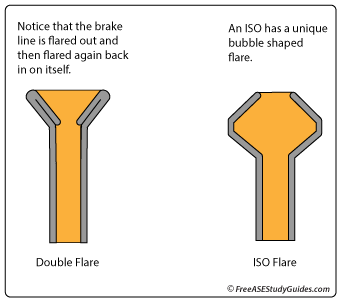

Each end of the line has a double (not single) or an ISO flare. It's easiest to use a prefabricated brake line that comes with the bends for that model vehicle.

Tube bending and flare kits create the bends and double flares in a new coil of brake line if a factory line is unavailable. Each of the two line flares has a unique flaring tool. For example, a double flare brake line flares out and back in on itself. Notice the ISO International Standards Organization looks more like a bubble. A brake line flare nut fastens these lines to the brake component or hose.

Brake tubing is rigid, so flexible brake hoses allow movement between the brake calipers and the fastened brake line. However, brake hoses can leak internally and swell, resulting in a spongy brake pedal. Replacement hoses come with new washers for a leak-free repair. Always replace the soft brass washers with the new washers provided.