Slipping Transmission Multiple Disk Clutch

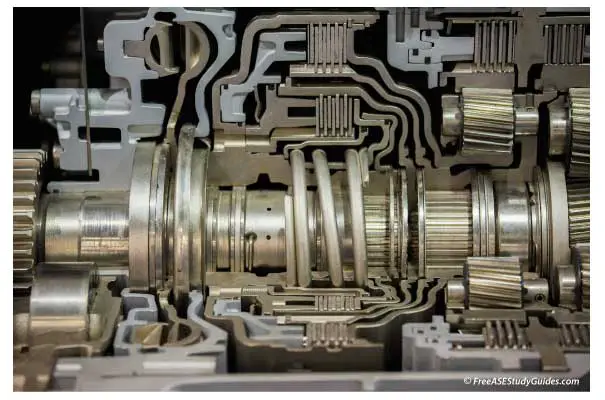

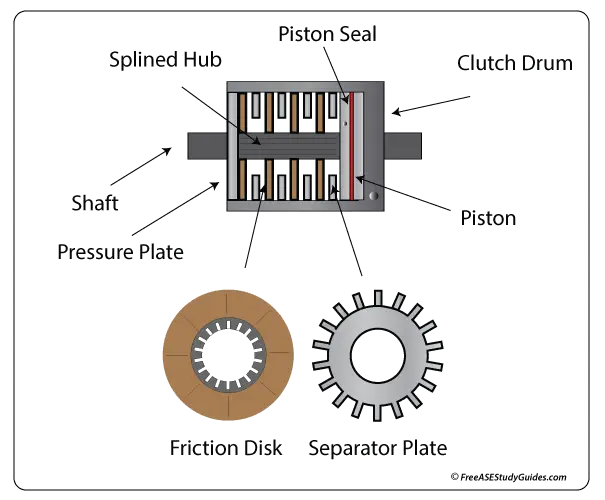

Automatic transmission multiple disk clutch assemblies drive and hold members of the planetary gearset. Holding clutches have steel tabs that fit into slots in the transmission case. They are considered case-held, grounded, or "locked" to the case. Others, assembled in a drum, drive a member of the gearset when applied. They both have a spring or set of springs that move the piston assembly back to its parked position when hydraulic pressure is released.

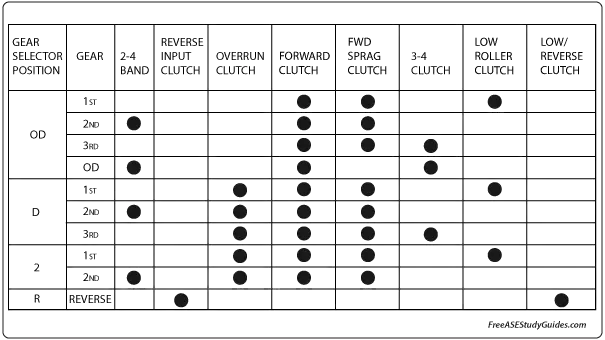

Tools like band and clutch application charts are used to pinpoint the area that's causing a problem. Through a process of elimination, a technician can find the faulty component using this handy chart.

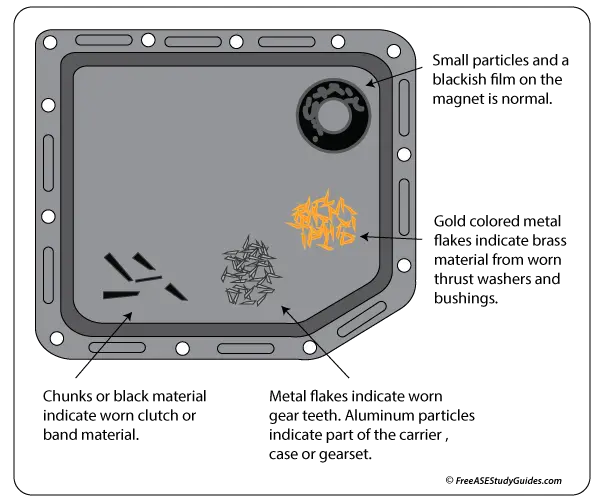

If the transmission is slipping, and the ATF is dark and smells burnt, suspect worn clutch friction discs. Worn and burnt clutch friction material discolors the ATF and appears in the oil pan's base as little black pieces in a dark sludge. Friction disks are splined on the inside and slide onto a hub. They are usually cellulose, with grooves cut into the surface to aid heat dissipation or semi-metallic or metallic material. Worn and burnt friction material from a slipping transmission smells burnt, turning the fluid dark and discolored.

Metal friction disks wear their mating steel plates sooner than the paper disks. The steel separator plates are tabbed on the outside and slide in the splines inside the drum. The drum can fail and separate where the snap ring fits, and debris can collect inside the drum, causing the disks not to slide smoothly and stick. Transmission components like the clutch drum discolor and turn dark blue when overheated.

When disassembling a transmission, it's important not to mix the parts of one clutch pack with another. Always inspect and clean the assemblies during and after removal. Friction disks are soaked in clean transmission fluid for about 20 minutes before reassembly. Review manufacturer specifications for proper procedures and clutch pack clearances, TSBs, or specifications.