Automatic Transmission Pressure Test

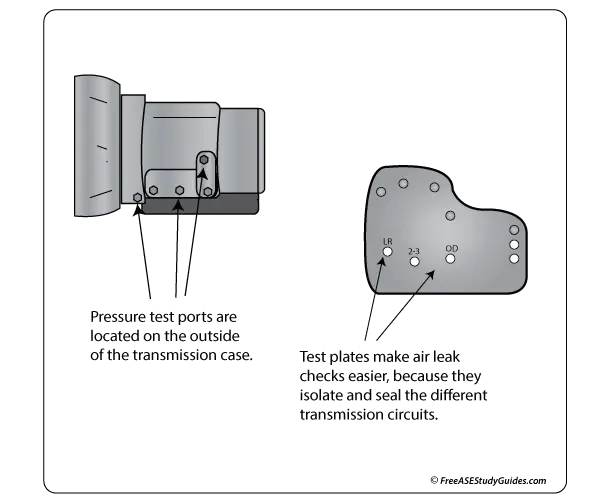

Most transmission cases have test ports to retrieve hydraulic pressure readings for the line, clutch, and servo circuits. The transmission's service manual provides these test port locations. They have bolt-like plugs screwed into them. Locate the desired port, remove the plug, and screw in the pressure fitting. A pressure test will indicate if line pressure is too high or low or if a clutch or servo leaks and loses pressure. Perform a pressure test on an automatic transmission when it suffers from hard shifting or poor shift timing.

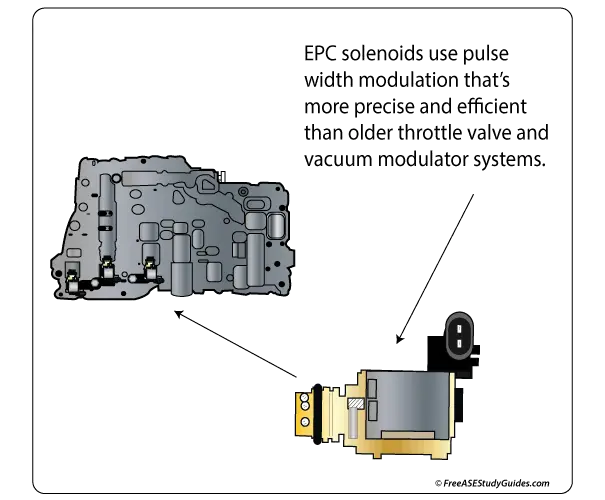

The vehicle's engine must operate correctly before diagnosing and troubleshooting a transmission. If the line pressure is low at idle, the pump or pressure relief valve is most likely the problem. Check to see if line pressure increases when idling up the engine. Electronically controlled transmissions incorporate an electronic pressure control solenoid to control line pressure. The EPC solenoid can be monitored with a scan tool and tested with a multimeter.

Use two 400 psi gauges to test a hydraulic clutch or servo circuit. Connect one to line pressure and the other to the holding device's circuit and monitor both circuits simultaneously. A pressure difference beyond specifications, usually 8-15 psi, indicates a hydraulic leak. Check the manufacturer's specifications before proceeding.