System Evacuation

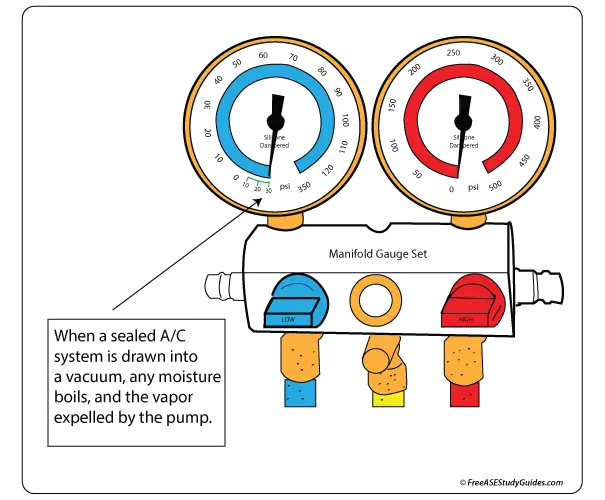

After the recovery process is complete and all available refrigerant has been removed from the system, it's ready for evacuation. When a system is severely low on refrigerant or has been opened and exposed to the atmosphere for repair, moisture, and air enter the system. Moisture and air are removed from the system with a vacuum pump to draw the system into a vacuum.

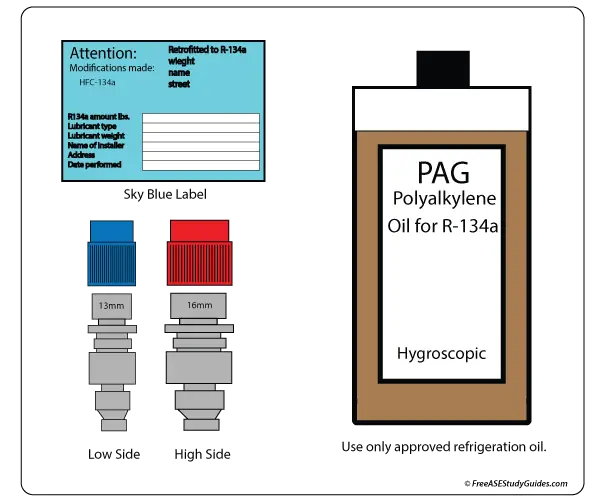

Moisture in an R-134a system mixes and reacts with the refrigerant and oil. It forms a corrosive hydrochloric acid that corrodes lines, clogs screens, and damages other components in the system. It blends with the hygroscopic oils used in today's R-134a systems, reducing their ability to lubricate components like the compressor. Performing an evacuation does not remove metal shavings from a system. Metal and debris require a flush.

A vacuum pump draws the system to a vacuum of 29.75 "hg or greater. Bringing a closed system into a vacuum reduces the boiling point, and any moisture boils into a vapor pulled out through the vacuum pump.

The system should be pulled into a vacuum for at least 30 minutes after being exposed to the atmosphere for repair. Check with the manufacturer's specifications. If a system is left open and exposed to humidity for a long time, increase the pump on time.