Radiator Pressure Cap

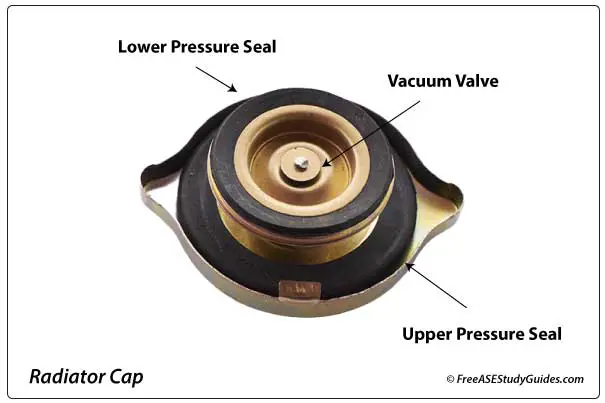

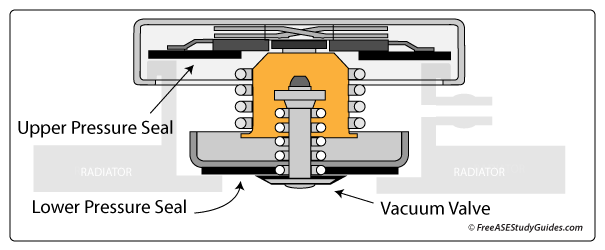

The radiator pressure cap prevents coolant loss and increases the cooling system's boiling point. It contains a spring that holds pressure in the system until it reaches a specified pressure. For every pound of spring pressure, the boiling point is increased by 3° F. Water boils at 212° F; increasing the pressure in a closed system increases the boiling point. A cap rated at 13 lbs. will increase the boiling point in a system by 39° F. High-performance caps range from 19 – 32 psi. Manufacturers can design engines with higher operating temperatures.

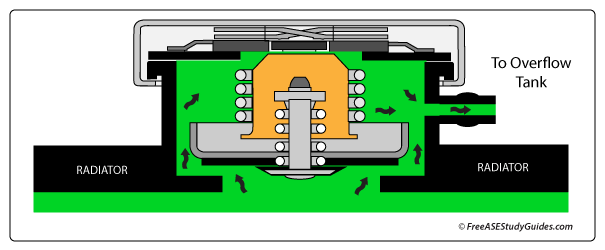

The radiator cap also allows the engine's coolant to expand and contract without allowing air to enter the cooling system. The upper seal seals and protects the system at all times. After the engine warms and system pressure reaches the caps pressure rating, the pressure spring allows pressurized coolant to flow into the reservoir or coolant overflow tank, allowing for the heated fluid's expansion.

As the cap wears, the spring weakens, and excessive coolant is allowed to flow into the reservoir tank. This coolant overflow will result in a loss of coolant. If the system passes a coolant system pressure test with no leaks in the engine or passenger compartments, suspect a faulty radiator cap.

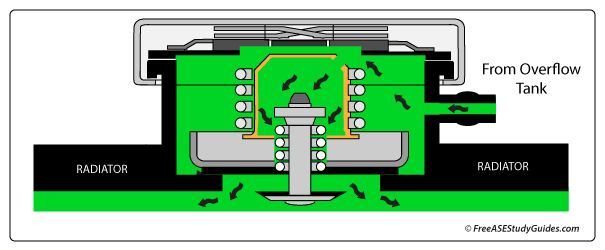

The cap also allows the coolant to flow back into the radiator as the engine cools. It contains a vacuum valve. As temperatures drop and the coolant contracts, a vacuum is created in the engine's cooling system. The vacuum valve opens, allowing coolant to flow back into the radiator from the overflow tank. As the pressure inside the system drops, outside air pressure helps the coolant flow in.

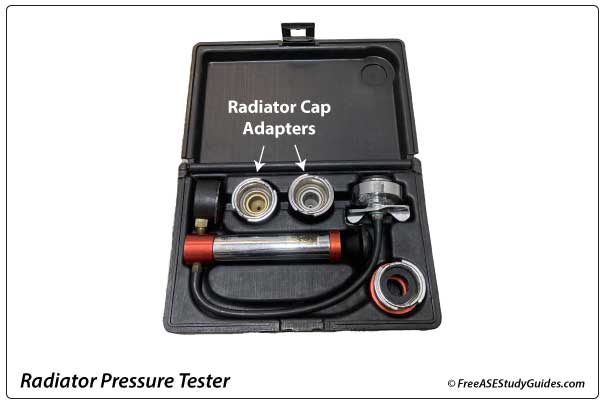

Radiator pressure testers apply pressure to the cooling system and typically have adapters that fit and test different radiator caps.