AC Compressor Noise

The AC compressor compresses and increases the pressure of the system's refrigerant before entering the system's high side. Common problems include noisy belts, squeaky bearings, scraping clutch plates, and buzzing sounds.

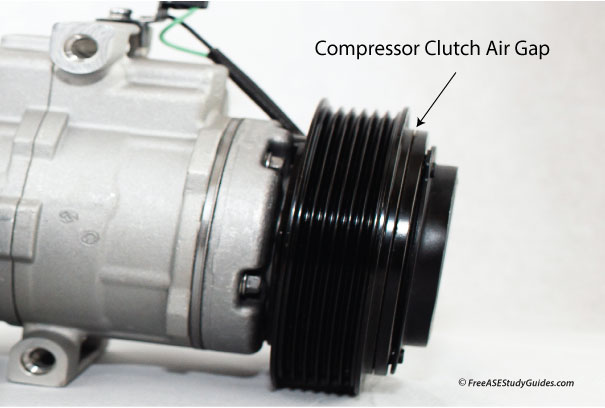

Worn AC Compressor Clutch

An A/C compressor clutch coil is a simple device made of fine wire windings wrapped into a coil. As current passes through the coil, a strong magnetic field pulls a splined hub into contact with the spinning pulley. This action engages the compressor.

The compressor clutch coil engages and disengages the compressor from the engine. When the ECM energizes the coil relay, it locks the clutch plate to the spinning pulley, causing the compressor shaft to spin.

The gap between the clutch plate and the spinning pulley must be within specifications. The clutch begins to slip as the gap increases, resulting in a scraping noise when the clutch is activated and the compressor is engaged.

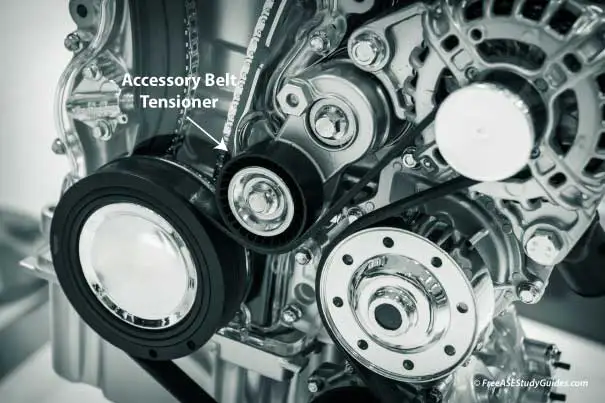

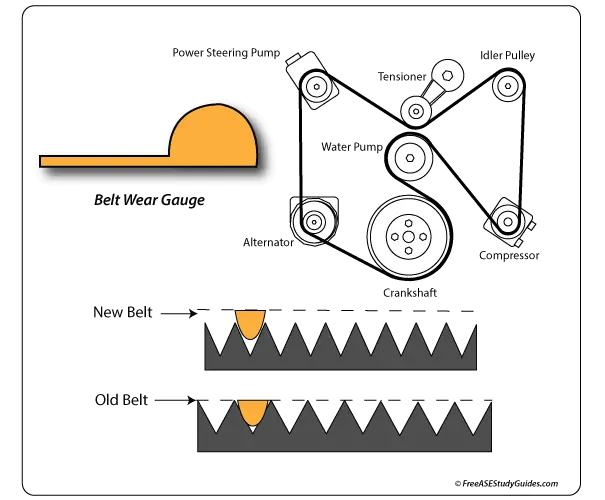

Worn or Loose Serpentine Belt

The accessory belt serpentines around the pulleys, and glazing, material wear, and cracking can appear on both sides. Inspect the accessory belt for cracks and excessively worn edges. Misalignment of a pulley results in excessive wear on the edge of the belt. This misalignment is common after replacing an accessory like the compressor or power steering pump.

Bearing Noise

The AC compressor and clutch contain bearings that, when worn, can squeal or grind while turning. A listening device like a stethoscope may be required to locate the faulty bearing. The belt tensioner and idler pulleys contain bearings that can squeak or seize, making noise or causing the belt to break. Remove the belt and check the pulleys for bearing noise and looseness.

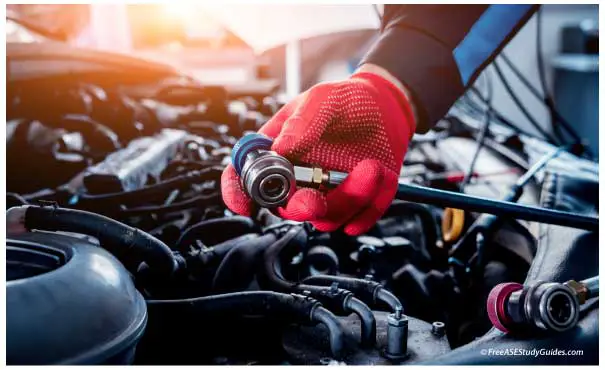

Refrigerant Overcharge

A refrigerant overcharge results in a buzzing sound. Liquid refrigerant enters the compressor, causing noise and vibration. The liquid is incompressible, and liquid refrigerant can damage the compressor. Return the system to the recommended charge to prevent internal damage.

Loose Mounting

Check for loose mounting, which can cause noise and misalign the pulley and accessory belt. A loose compressor will make a rattling or clunking sound, mainly when the clutch engages. Remove the belt and look for wear around its edges caused by pulley misalignment.