ABS Hydraulic Control Valves

During normal braking, the electronic brake control module or EBCM monitors wheel speed for skid or lockup. If an impending skid is detected, the EBCM activates solenoid valves in the hydraulic modulator to prevent the tire from locking up and skidding.

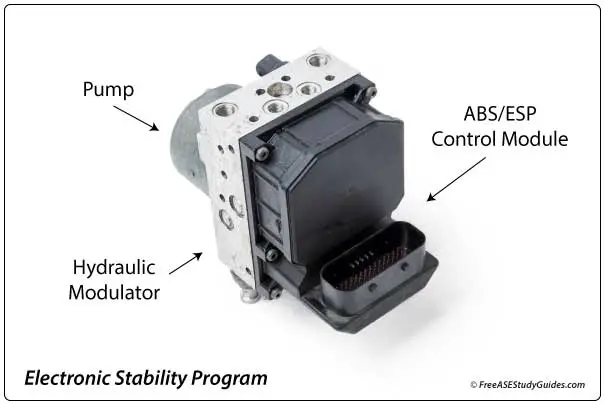

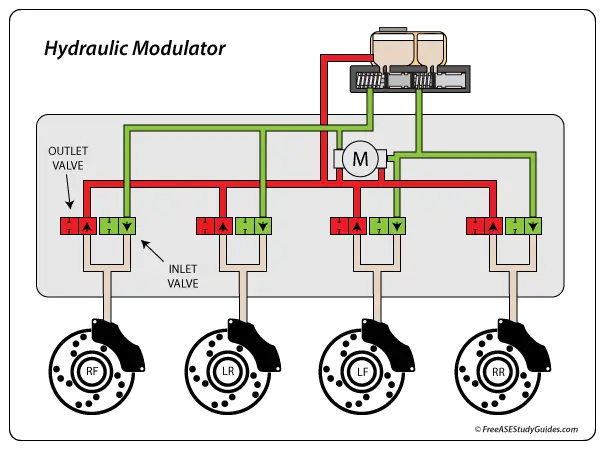

The hydraulic modulator below contains two valves for each brake caliper. Some modulators include a single three-way valve, and others have two valves per brake unit.

They have an open inlet valve that allows fluid to flow from the master cylinder through the valve and to the brake units and a normally closed outlet valve that blocks fluid from flowing back to the accumulator, reservoir, or pump. During normal braking, the inlet valve remains open, the outlet valve remains closed, and flow to the brake calipers is unaffected.

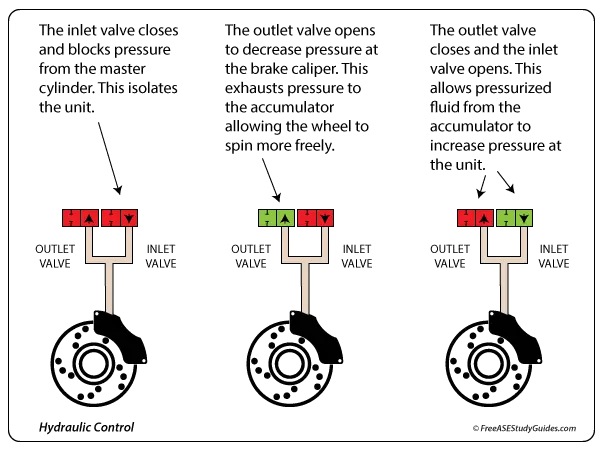

During a panicked and hard braking situation, the ABS operates these valves to prevent a wheel or wheels from skidding. If a wheel is about to skid, the inlet or isolation solenoid valve is activated to block off flow from the master cylinder and maintain pressure in the brake caliper.

If the tire is about to skid, the outlet valve is activated even after isolation mode, and fluid pressure from the brake unit is exhausted to the accumulator. Closing the outlet valve and opening the inlet valve restores pressure to the caliper. This process happens rapidly and sometimes causes a pulsation in the brake pedal.

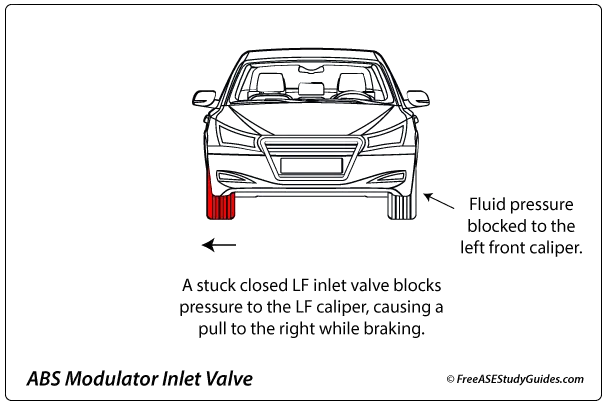

Sticking valves and solenoids can cause pull while braking. For example, a sticking or stuck closed inlet (isolation) valve will block the flow of brake fluid to a front caliper. As a result, the vehicle will pull to the opposite side when the brakes are applied. Likewise, a stuck open outlet valve to the LF caliper will dump fluid pressure from the caliper, resulting in a soft pedal and a slight pull to the right while braking.