Power Steering Systems

Automotive power steering systems have evolved from hydraulic to electro-hydraulic to all-electric. The troubleshooting procedures have changed. Fluid leaks are the biggest concern with hydraulic to electro-hydraulic systems. Modern EPS systems have no fluid and are more likely to have electrical, motor, and controller issues.

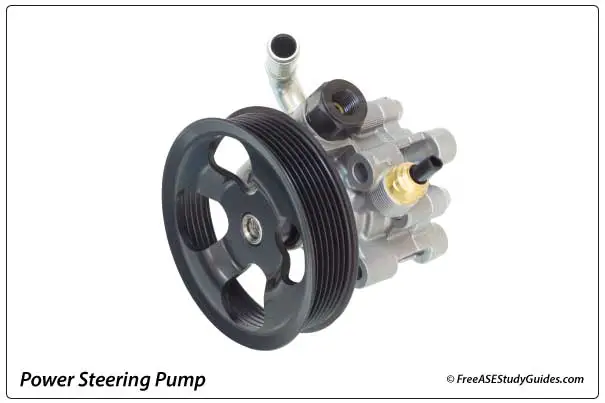

Hydraulic Power Steering

Hydraulic power steering systems use a belt-driven pump to create hydraulic pressure. The high-pressure hose delivers power steering fluid under pressure from the pump to the gearbox or rack and pinion gear, and the fluid returns to the pump through the low-pressure line.

Variable assist power steering systems provide maximum assist while parking and a firmer feel as vehicle speed increases and at highway speeds. There are different designs and names for these systems. They reduce the steering gear or rack pressure with vehicle speed. As vehicle speed increases, the control unit restricts fluid flow to the steering gear system. This action reduces the chance of oversteering and gives the vehicle better stability.

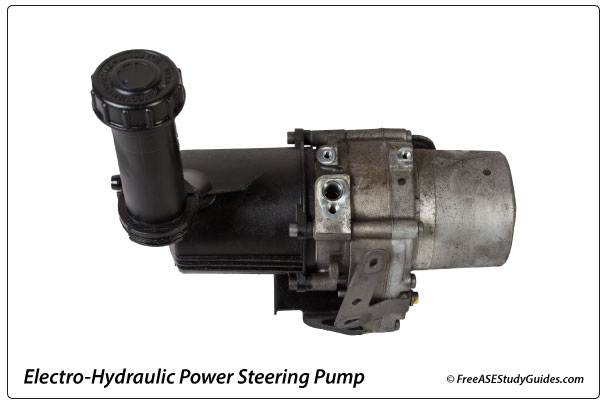

Electro-Hydraulic Systems

Electro-hydraulic power steering systems are hybrid and have an electric instead of a crankshaft-driven pump. The computer-controlled pump increases pressure at low speeds and reduces pressure for a firm feel on the highway. It improves fuel mileage and has no drag on the engine. The systems still use hydraulic fluid and should be inspected for leaks. There are no hydraulic fluid leaks in newer EPS systems. They are electric, with motors and reduction gears that drive the column, rack, and pinion gear directly.

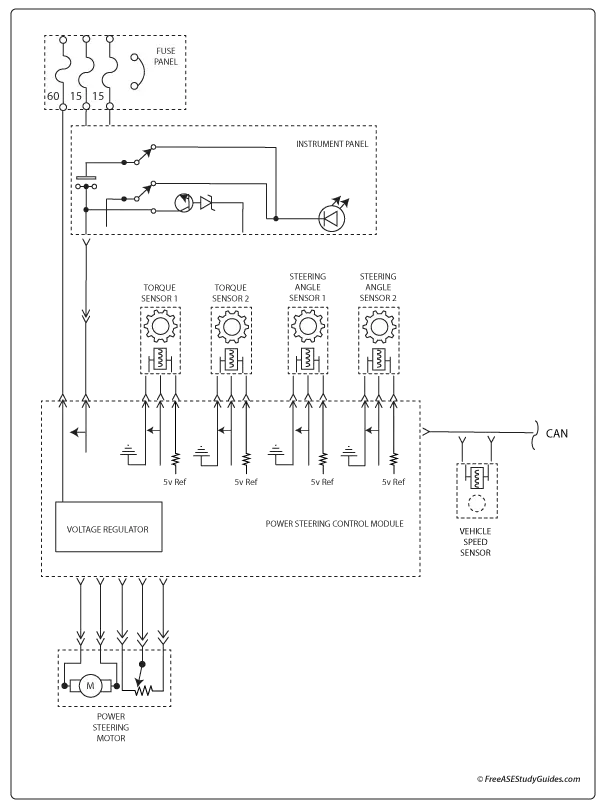

EPAS All-Electric Power Steering

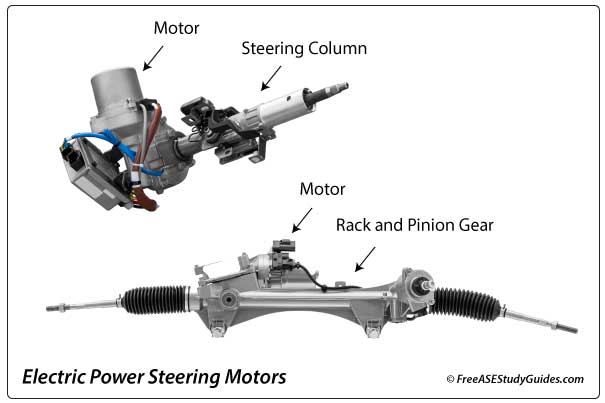

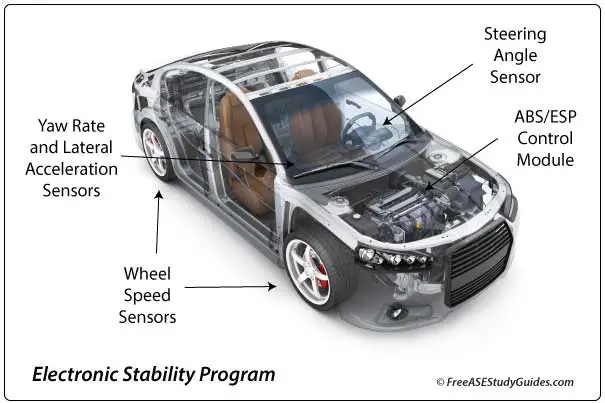

Many late-model vehicles have EPAS Electric Power Assist Steering that uses an electric motor instead of a pump and hydraulic pressure to provide power steering assist. The EPAS control module uses inputs from the steering torque and angle sensors, indicating the speed and effort required to turn the steering wheel. The module uses these and the vehicle speed sensor input to control the motor.

The motor is on the steering column or the gear. An electromechanical unit is entirely electric, and no hydraulic fluid is required. Instead of the crankshaft, the alternator provides the voltage required for operation. EPS is economical, offering higher fuel mileage.

Lane Keeping and Park Assist

EPS works with electronic stability and automated systems like lane keeping and park assist. Like variable assist steering systems, voltage is increased during parking maneuvers and slow speed operation and decreased, reducing assist and providing a tighter feel approaching highway speeds. While test-driving a vehicle with EPAS, the steering should feel progressively tighter as vehicle speed increases.