Internal Shift Linkage

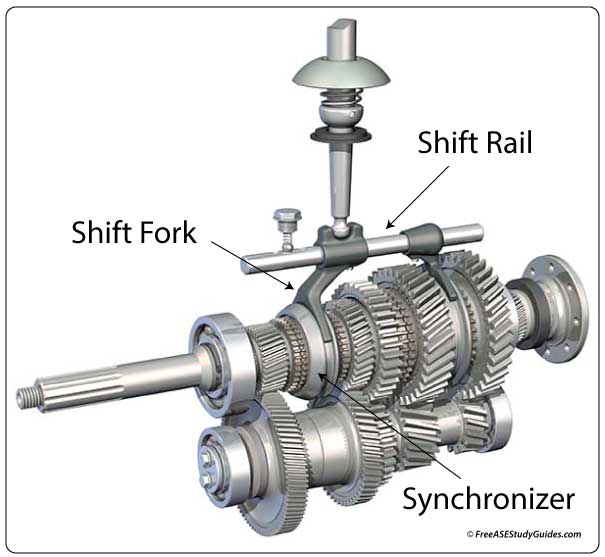

Manual transmission shift rails connect the shift lever to the fork. When the driver moves the shifter to select a gear, the shift rail moves a shift fork attached to a synchronizer. Each synchronizer is capable of changing two-speed gears. Most five-speed manual transmissions have three shift rails.

Shift Rails

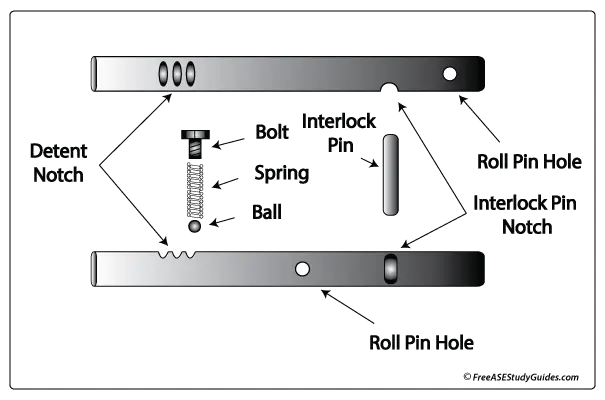

Shift rails have detent and interlock notches machined into their sides. A spring-loaded ball fits into the detent notch to lock the transmission into gear. The vehicle will jump out of gear if the ball slips out of its notch. The rail should slide easily in its bore but with no lateral up-and-down or side-to-side movement. While in the desired gear, the interlock pin prevents the transmission from shifting into another gear. For instance, while the first/second gear shift rail is moved, the third/fourth gear rail is stationary.

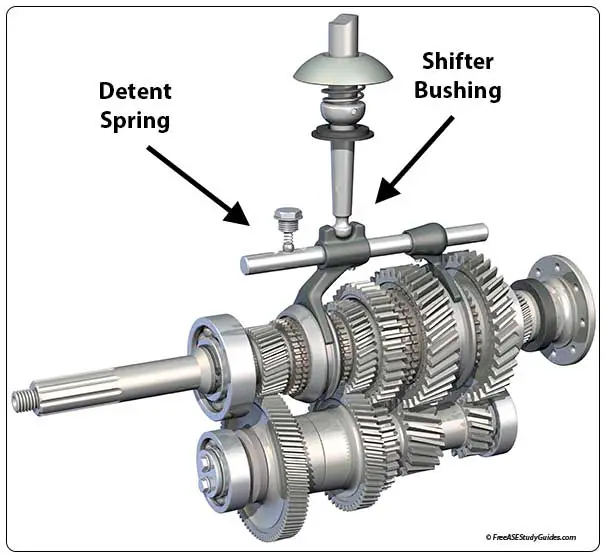

Shifter Bushings

Check the ball and spring for wear and tension because a weak spring or worn ball results in the transmission jumping out of gear.

Shift Forks

Shift forks are attached to the shift rail by roll pins. Before attaching the forks to the shift rail, ensure they slide along smoothly. Not binding, smooth, without side play. Check the forks, gates, and the rails for bends, cracks, and excessive wear. Transfer cases also use shift rails with detent ball springs. They're used to shift between high and low gear ranges. The notch, check ball, and spring are used and inspected like the internal linkage of a manual transmission.