Pinion Bearing Preload

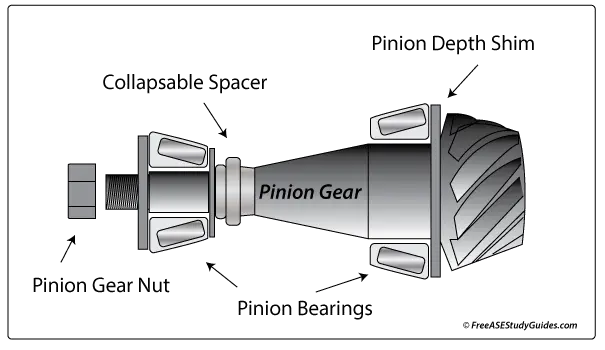

Pinion bearing preload is the tension on the pinion gear's tapered bearings. A collapsible spacer is used to obtain the specified pressure or preload. This spacer is placed between the bearings. Turning the pinion gear nut crushes the spacer to obtain the specified preload.

This preload prevents the sideways thrust that moves the pinion gear to the outside edge of the ring gear. It acts as a spring to counter this motion. Some heavy-duty and more demanding differentials have a solid spacer instead. This type of spacer must be the appropriate size to obtain proper preload.

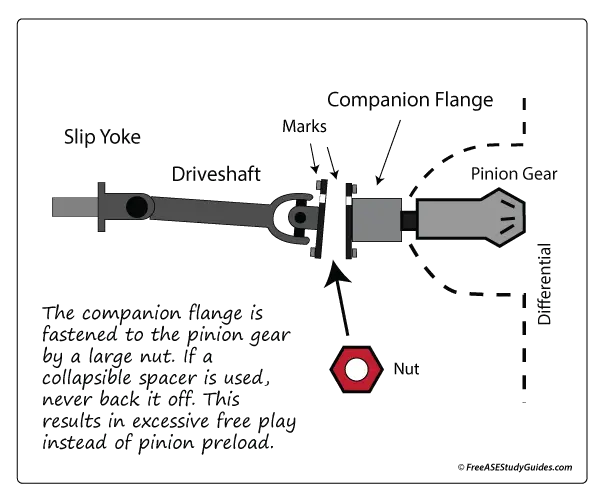

The collapsible spacer can only be crushed once. The pinion nut cannot be overtightened and backed off. The slack would leave the pinion bearings with little or no preload. It takes considerable torque to turn the pinion nut, and it can be tricky towards the end. Once the companion flange feels snug, turn the pinion nut in 1/8 inch increments, and then, with each turn, check the turning tension with an inch-pound torque wrench.