Manual Transmission: Gear Inspection

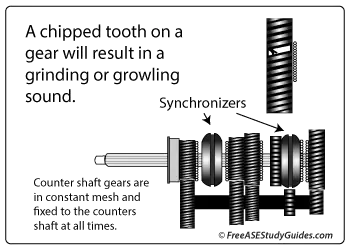

Inspect all gears for nicks, chipping, and galling. Small nicks and chips can often be filed and smoothed out of the gear's teeth. The entire gear must be replaced if the chip is too deep to file. Each gear should be inspected inside the cone area where the gear rides on the shaft. Inspect the dog teeth for excessive wear.

Worn and rounded gear teeth cause a growling noise. This noise may be evident in all gears but is more pronounced when it's the selected gear. It's because today's transmissions are in constant mesh.

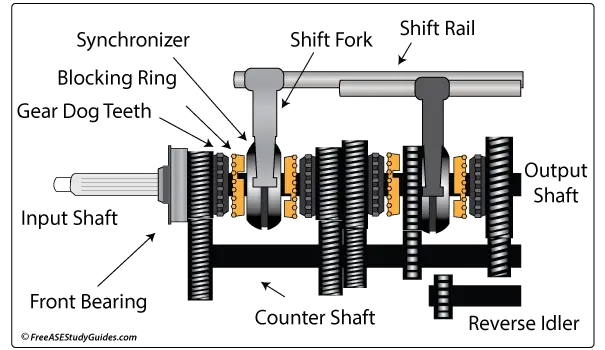

A synchromesh transmission uses synchronizers to change gears. In the old days, the driver had to mesh the gears by double clutching. This practice would get the two spur gears to match each other's speeds before engaging. These older spur gears made much more noise than the constant mesh helical gears today. Many transmissions use spur gears for reverse. This is why many vehicles make a different sound when driven in reverse.

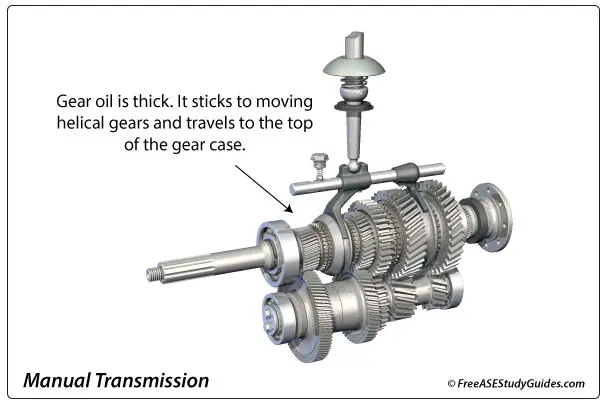

Inspect the dog teeth of the gear for rounding. It results in hard shifting. Inspect the cone of the gear where the gear rides on the shaft. The gear rides on a series of needle bearings. Ensure these bearings and the inside of the gear are not dark bluish-colored. These bearings turn blue from excessive heat. Use only the recommended oil in any transmission. Too thick of an oil causes hard shifting and is more prominent when cold.