Limited Slip Differentials

A limited-slip differential locks the two rear wheels together while traveling in a straight line for increased traction. Because the outside wheel spins faster during a turn, it allows one wheel to slip while turning. During a turn, the wheel on the outside rotates ~10% faster than the inside wheel. The two wheels can rotate at different speeds during turns by overcoming clutch tension. They provide better traction on slippery surfaces.

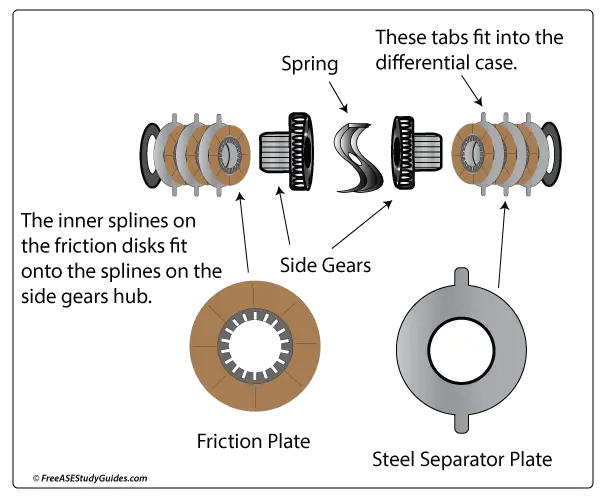

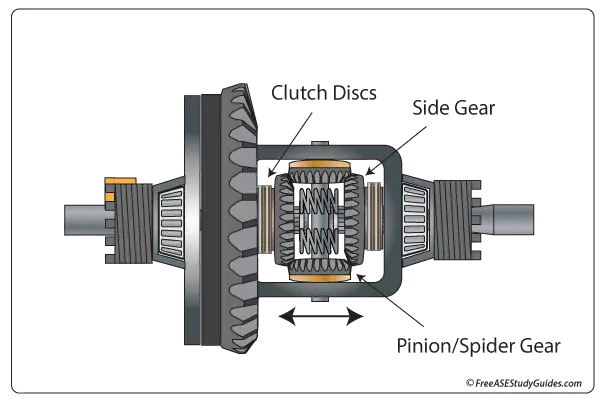

Some contain cones, and others have friction plates. A multiple-disk clutch differential consists of two sets of multiple-disc clutch packs on each side gear. These clutch packs have friction plates splined to the side gear, interlaced with steel plates that have tabs locking them to the differential case.

The spider and side gears are beveled. The turning pinion gears force the side gears outward toward the case. The mechanical force of the beveled gears and spring tension apply to the clutch. For a set of friction plates to slip, they must overcome the preset spring tension.

Service the differential fluid at recommended intervals. Special limited-slip differential fluid compliments the engagement and release of the limited-slip components. Adding standard differential fluid to a limited-slip differential can result in noise and vibration while turning.