Cylinder Bore Measurements

Today's vehicles have extremely tight maximum allowable clearances. The cylinder's taper and out-of-round dictate whether a cylinder is acceptable or if the engine block needs to be bored. Measure cylinder bore roundness and taper with a cylinder bore gauge.

Cylinder Wear

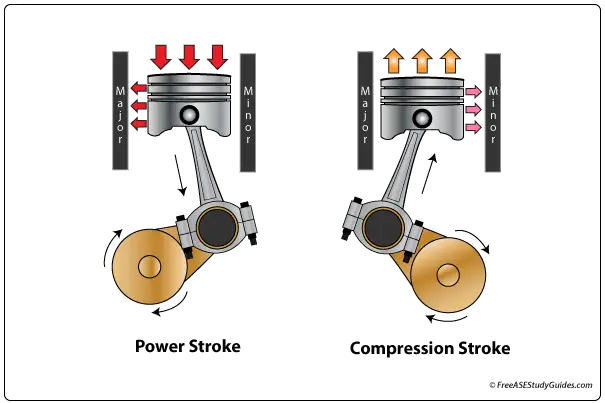

A new cylinder wall is true and perfectly round. It must be in excellent condition before piston installation. A worn cylinder is worn more on its top and thrust side of piston travel.

Pressures exerted at the top of the ring travel, and the major and minor thrust surfaces take their toll over time. The pressure is most at the top and points 90° to the piston pin.

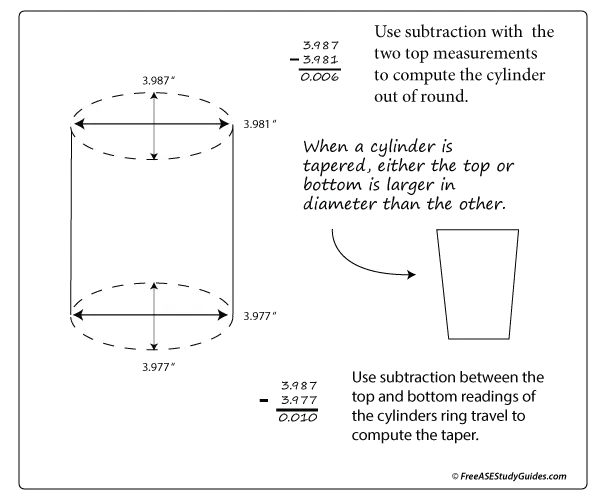

Measure Taper and Out of Round

Less oil reaches the top of the cylinder resulting in more wear. Taper is the difference in the diameter between the top and bottom of the piston ring travel. Take measurements at the top of the piston ring travel, and compare them to the measurements at the bottom of the piston ring travel. Taper causes excessive piston ring movement as the piston travels up and down the cylinder.

Out-of-round is the difference between the thrust and non-thrust surfaces of the cylinder wall. Record out-of-round and taper measurements before and after honing or reconditioning the cylinder walls.