Clutch Pressure Plate

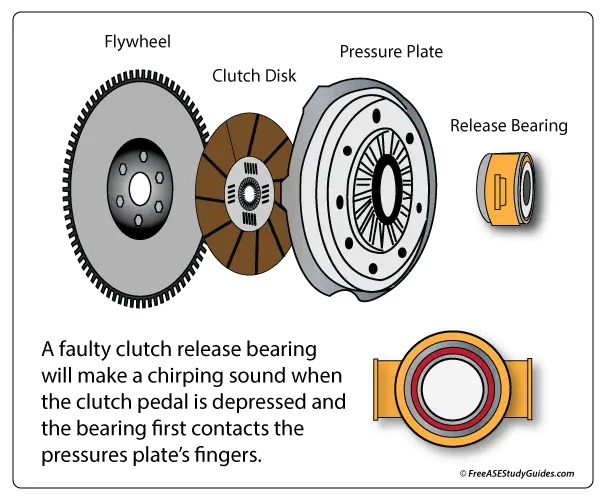

Pressure plates must be carefully inspected before returning to service. An initial visual inspection of the pressure plate, clutch disc, and flywheel can usually be done through an inspection cover. To inspect the plate's surface, separate the engine from the transmission and remove the pressure plate from the flywheel

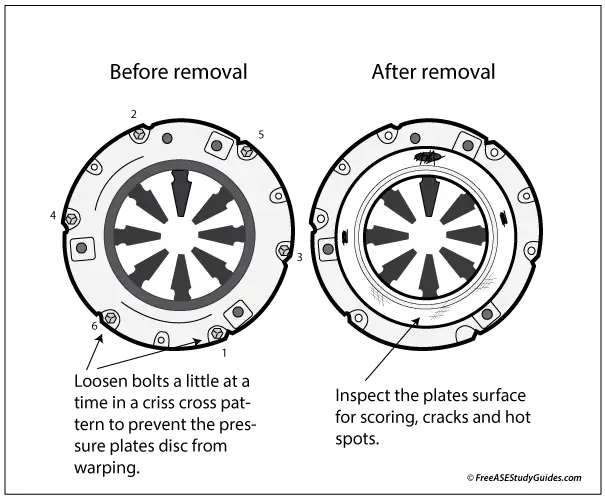

Remove the pressure plate bolts a few turns at a time and in a crisscross pattern. Failure to do so can result in a warped pressure plate. Inspect the pressure plate for warping and hot spots. This part is often replaced when replacing a worn clutch disc.

Inspect the plate's surface for cracks, scoring, and chatter marks. They leave dark and then light spots around the plate's surface. This can be the result of a worn disc or incorrect free-play adjustments. Free play is the distance between the release bearing and the pressure plate fingers. Anytime the clutch slips, it creates heat and damages the pressure plate's surface.

A defective or worn release bearing can cause excessive wear on the diaphragm's fingers. These fingers fan out as the disc wears, reducing free play and riding on the release bearing. For constant running release bearings, refer to the manufacturer manual for specifications.

The flywheel can be removed from the vehicle and resurfaced as long as it is within specifications. Disassembling and resurfacing the pressure plate may be hazardous due to intense spring pressure and should be left to the machine shop.