Accessory Belt Wear

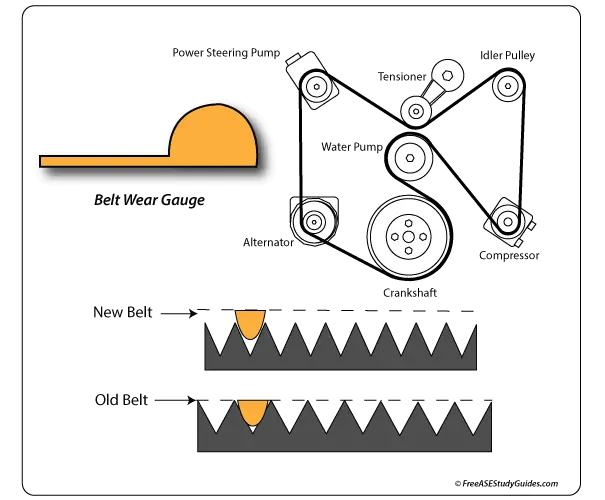

Today's EPDM accessory belts have extra elasticity, making them much less vulnerable to cracking. The accessory belt drives the alternator, power steering, air conditioning compressor, and more as it serpentines or snakes around pulleys on the front and back sides of the belt.

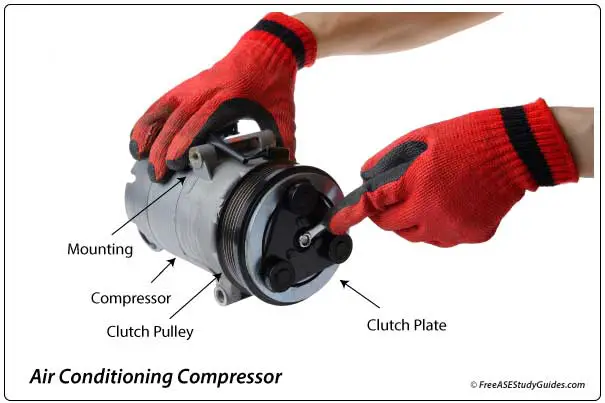

Check the accessory belt and tensioner for a chirping sound when starting the engine with the air conditioning ON. Also, inspect the belt and clutch pulley bearing for a squeal when turning the air conditioning ON with the engine running.

A good belt rides a little above the pulley to allow dirt and debris a pathway out of the belt system. As the belt wears, the gap between the pulley and the belt begins to decrease, preventing dirt and debris from leaving the belt system and resulting in a loss of belt performance.

A belt wear gauge measures the depth of the belt. On a new EPDM serpentine belt, the gauge rises above the ribs. If the belt is worn, the gauge sinks into the belt, indicating the need for replacement.