Valve Stem Installed Height

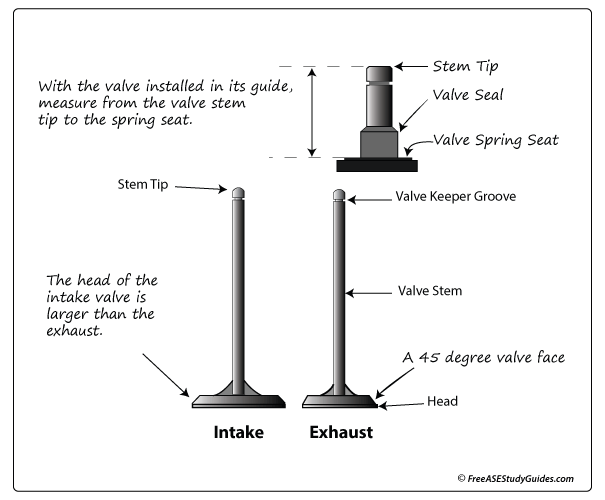

Valve stem installed height is the measurement from the tip of the valve stem to the valve spring seat or cup. All valve stem heights must be within specification.

If one valve stem is higher than the others, suspect that the valve face or seat is worn. A valve stem height gauge may be required to measure this height.

The seal between a valve and its seat must be very tight. A tight seal provides for good heat dissipation.

An interference angle is created by cutting the valves at different angles. It guides the valve into the seat and seals the cylinder with the appropriate pressure.

Valve stem installed height is essential because it affects the geometry and volume of the combustion chamber. It also affects lifter preload, spring height, valve lift, and the life span of the valve train in general.

Many manufacturers recommend that valve tips be ground if necessary. There's a limit to how far a valve tip can be ground.

Replace the valve if the distance gets too close to the retainer or rotator. It may be necessary to remove the old seat and install a new one to bring measurements back to specifications.

Check the condition of the valve's tip and make sure all appears normal. Check valve stem installed height any time the valves or seats have been replaced or machined.

Valves become stretched at the neck just above the fillet. This stretching is known as stem necking. It's the result of hot exhaust gases swirling around the neck.

Valve stem installed height is different than valve spring installed height. Valve spring installed height is taken from the underside of the valve spring retainer/rotator to the valve spring seat.